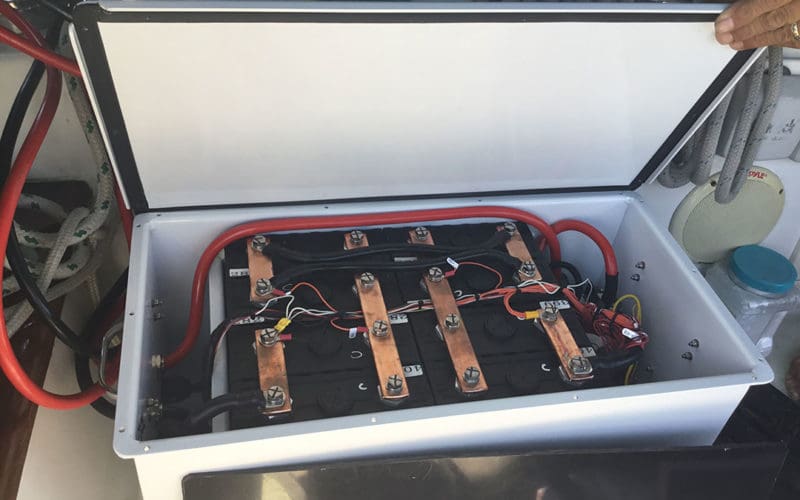

Earlier this year, I finally upgraded from lead acid batteries to lithium iron phosphate (LiFePo4) batteries on my Valiant 40, Brick House. I’d researched for at least a year and South Africa, with its great tech base and good exchange rate, was the place to do it.

Lithium batteries favor the inclusion of a battery management system (BMS) in most applications on boats. The BMS ensures that the battery is not over or undercharged, and that it doesn’t overheat, freeze, or have to deal with oversized currents. Most people understand that a lithium battery BMS is the brains of the charging/power storage operation and will protect the batteries and everything else in the system. But what many fail to understand is that the BMS is not perfected to protect much more than just the batteries. Further measures must be taken to protect both the batteries and the surrounding components.

Many battery manufacturers will tell you that the charging sources installed on your boat will work perfectly with their batteries. In reality, they know your charging sources won’t damage their batteries because ultimately the BMS will be programmed to shut down charging or discharging of the batteries before damage can be done. The BMS, on the other hand, does very little to protect your charging sources, such as your alternator, solar or wind chargers, wiring, or electronics. Whether in the middle of the ocean or anchored in a remote location, a cruising yacht is almost entirely dependent on alternative energy to run important life-supporting systems. It cannot undergo a failure of the energy storage system and still remain safe.

Protecting your sources

Charging sources can be permanently damaged when they are run at full blast for too long to charge your less-than-fully-charged lithium batteries. Lead acid batteries demand much less in the last 10% to 20% of charging and will tax these systems lightly. But lithium ion or LiFePO4 batteries seek charging at full speed ahead until they are 100% charged. One must give careful consideration to the charging source’s future health during an upgrade to lithium batteries, because while those same chargers will push power out as hard as requested, the chargers are not designed to run at 100% output for an extended period. At worst, a charger will be ruined quickly; at best, it will prematurely wear out over time running continuously at full output.

Likewise, the wiring that carries this charge to and from the chargers must be of heavy enough wire gauge to continuously carry the additional heat from prolonged full blast charging. There is also the consideration of making sure each of the charging systems can properly charge the batteries to the manufacturer’s spec, not to an arbitrary battery profile that prematurely wears out the batteries. This includes alternators with internal and external regulators, MPPT and PWM solar chargers, as well as wind generators, trolling chargers, and onboard or portable generators. A “lithium” profile on the charger is most often inappropriate, despite the claims of the manufacturers of these units. Every battery manufacturer has tested their batteries to define the optimum charging profile, while a charger manufacturer has no idea what is required for each particular brand of battery.

Lithium battery profiles

Many default “lithium” profiles are set to obtain the highest charge allowed to the majority of lithium batteries as defined in a certain point in time — they may not be set at the optimal charging voltage for your specific battery as currently recommended. This technology has changed quickly, and many battery manufacturers are now recommending lower optimum voltages. The BMS itself should rarely, if ever, be relied upon to shut off charging. This means charging has gone too far and emergency measures had to be taken. This should be controlled long before it ever appears on the radar of the BMS. The BMS should be considered an emergency shutoff only; a safeguard to prevent a fire or explosion. The fire brigade should not be relied upon on a daily basis! The optimum charging and protection should come from properly choosing, installing, and programming the charge controllers.

Your charging sources themselves must be programmed to charge the batteries properly, tapering off charge long before the BMS comes into play. Many chargers have “LiFePO4” or “lithium battery” charging profiles. Many charger manufacturers believe charging at 14.6 volts for example, is ideal for all LiFePo4 batteries. My Freedom Won LiFePo4 batteries are never charged beyond 14 volts, and I often dial it down to 13.8 volts if I’m on shore power for extended periods. Often, the newer LiFePO4 batteries take 14.2 volts on the upper side, but they should not be charged higher than this according to the manufacturer. In fact, the BMS shuts down at 14.2 volts. Therefore, some charging sources set at 14.6 would never even get fully charged before being shut down. Some batteries don’t just shut off the charging, but instead shut down the entire battery — and so your bilge pump, your alarm system, and your refrigerator will be left with no power until you manually reset the battery. And if set at below 13.8 (for my specific batteries, for example), the internal cells would never balance with each other, as balancing is only initiated by the BMS when the voltage is above 13.8 volts. Hence, over time the internal cells of the battery would fall out of balance, potentially setting up an unsafe condition. If I set the charger to the “LiFePO4” profile, my batteries would be very unhealthy very soon!

The most important preparation you can make for lithium batteries is to check your charge controller and make sure they have a “custom” battery profile where the charging voltages can be tweaked to your battery manufacturer’s specs. You don’t want to be stuck with just one profile setting as defined by the manufacturer of that controller, who may or may not know anything about your specific lithium batteries. It could be very damaging and costly, if not dangerous, to not be able to modify the charging profile as necessary. Something as simple as voltage drop between charger and battery could wreak havoc. This would then require changing settings to accommodate for the difference. That would not be an option with no custom settings capability.

Taking care of the alternator

One charging source at particularly high risk is your alternator. With lead acid batteries, the last 10% to 20% of the battery capacity in amps will only be charged very slowly, and the alternator is ever so happy for the breathing room. The batteries simply don’t call for much current when they are up to 80% full. So your alternator relaxes what it puts out — because the batteries are not thirsting for much. Lithium batteries are just the opposite. They request 100% full blast current, and if the alternator is willing to pump it out, the batteries will take it full blast until almost 100% charged. This in turn will cause premature if not instant failure of the alternator, because it will work hard at full output for too long. The alternator or charging cables could heat up beyond tolerable levels, causing potential failure or fire.

Balmar has a great solution to prevent such damage with its MaxCharge 614 Alternator regulator. The unit has alternator temperature regulation in combination with built-in belt manager software and completely programmable battery profiles, including a customizable one for LiFePO4 batteries. The belt manager software allows the boat owner to easily limit what percentage of maximum output the alternator is allowed to produce. Limiting the percentage of the alternator’s output capacity, however, by utilizing this belt manager software on our existing 100-amp alternator, would leave it charging at 50 amps — comfortable for the alternator, but hardly worth running the engine. So, we upgraded to a 170-amp alternator and, even if utilizing the belt manager at just 50% output capacity, we would still be putting at least 85 amps into the batteries. If we adjusted the belt manager up higher, after careful incremental testing, we would put even more amperage into the battery storage system at a faster pace. After some careful testing, combined with the alternator controller and temperature regulation settings, I have the belt manager set to 80% capacity and the alternator temperature set a bit below the recommended settings. This keeps the alternator from overworking and thus extends its working life considerably. I could likely push it even harder, but with the increased capacity I don’t really need to.

The other issue with using lithium batteries on a sailboat while using an alternator for charging is that if the voltage has not been properly controlled before the voltage/amperage shuts down the batteries via the BMS, the alternator suddenly has no place to put the charge, causing the alternator to quickly and suddenly smoke. I went through extensive measures to make sure my expensive alternator would be protected in every single situation.

Three protection strategies

The Balmar MaxCharge 614 alternator regulator is by far the most critical protection. We considered other regulator brands, but a Balmar regulator truly had the most tried and true, reliable, world-serviceable solution, and we decided it was the most reliable product on the market. This is what offers the alternator temperature regulation (not to be confused with battery temperature, which is not applicable with lithium batteries) and the belt load manager, which allows the throttling of the output of the alternator. This by itself would likely be enough. But I am a worrier and felt compelled to take it a few steps further.

The second form of protection I installed was a simple relay (which Balmar suggested to me) between the controller area network bus (CAN bus) inside my battery system and the alternator regulator. CAN bus is the central network of the battery system, enabling communication internal and external to the battery. The CAN bus inside my batteries sends a programming signal to the relay (Freedom Won inserted this into the system for me). The relay, in turn, directs the Balmar alternator regulator to gracefully power off in less than a second, which depowers and switches off the alternator. And then no harm can be done. It’s a very simple, fail-safe, and robust system.

My third form of protection, just to be sure, is a Sterling alternator protection device. If a cable comes loose, or a fuse blows, or the alternator is automatically disconnected from the battery, which can cause a completely destructive spike in the alternator.

The simple relay, the Sterling unit, paired with the all-important Balmar MaxCharge 614 external regulator, provides triple protection for my nice new alternator.

There is actually a fourth device that I have installed. Two additional battery monitors were installed in plain sight so that I could easily glance at the battery status every time I walked past. One is a Victron 712 Bluetooth monitor, and the other is a Victron Color Control (CCGX).

The other charging systems on the boat do not require quite the protection that the alternator does. But the chargers do require care in how they are charging the batteries. The BMS must not be utilized except in a backup capacity, and the chargers need to not conflict with the settings of the BMS. Wires must be upgraded if they are not of a large enough gauge. All devices should have independent fuses or circuit breakers.

Note: Before the passing of Patrick Childress on Brick House last year, Patrick and Rebecca upgraded their batteries to lithium batteries. Rebecca designed the system and ordered the necessary components for the installation. Rebecca also directed the installation while Patrick did the hands-on installation. n

Rebecca Childress is a regular contributor to Ocean Navigator and lives aboard the Valiant 40 Brick House. She has a video channel, Sailing Brick House, on YouTube.