If there is one thing that sets a yacht apart from all others in a cruiser anchorage, it is the vessel’s capacity to draw saltwater directly from the ocean and transform it into fresh water. That one key ability, drawing its power from one of multiple possible sources, ensures long-term independence from the hassle of filling and carrying jerry cans with water, sometimes of dubious quality, at every anchorage encountered on an ocean cruise.

Some skippers try to solve the water availability conundrum by simply storing extra water, sometimes hundreds of gallons, with extra tankage below deck. This can weigh the vessel down excessively, reducing speed and taking up room that could otherwise be used for storing gear or providing extra bunk space.

In days of yore, the only way to draw fresh water from ocean brine was through distillation—boiling and then decanting the steam into liquid water via a cooling tube. This was a slow, energy-wasting and dangerous system given to the occasional explosion, causing serious injury and destruction. Today, there are land-based facilities carefully designed and controlled to produce drinking and distilled water, alcohol and other liquids. On a boat, however, our best bet for constant access to fresh water is a reverse-osmosis watermaker system.

How reverse-osmosis works

One day while I was sailing in the South Pacific during a rough storm at sea, ocean water entered through a stanchion bolt hole on Saltaire’s foredeck, soaking a stack of clothes from the bottom up in the v-berth. Just for the heck of it, I tasted a wet t-shirt from the top of the stack and got quite a surprise. No salt! Just fresh water!

As the seawater had risen up through multiple layers of cloth, it had gradually shed its salt, leaving only clean, potable water at the top of the stack. The many layers of cloth had formed a semi-permeable membrane, inducing the wicking process in a manner not much different from that used in a modern desalinator, or “watermaker.” Now, add an electric pump to force that water through a purpose-designed, semi-permeable membrane (not a t-shirt), and voilà, you have a modern reverse-osmosis system.

In a reverse-osmosis watermaker for offshore vessels, sea water is first drawn up from under the hull through a scoop strainer where it passes through a feed pump and then into a pre-flush chamber where large particles of debris are filtered from the water.

From the pre-flush chamber, the partially filtered water then proceeds to a secondary filter for further clearing of fine particles from the brine. At this point, the water is clear enough to be introduced into actual reverse osmosis, the final and most important stage of purification.

In the final stage, water passes through an ultra-fine filtering membrane, which allows only water molecules to pass through to the output hose. The pumping process forces leftover brine discharge back into the ocean via hose and through-hull fitting.

If there is one potential downfall to this system, it is the lack of essential minerals we need in order to stay healthy during our ocean cruise. As a matter of fact, purified water can actually draw minerals out of your body, making matters worse. To correct this deficiency, add mineral drops, which contain a small amount of calcium, magnesium and, ironically, salt, which are essential to your health. And as a side note, your treated water will also taste a lot better.

Types of watermaker systems

Marine watermakers are generally categorized by the type of power they use, DC, AC or mechanical, the last of which is provided directly by the propulsion engine. Most of the smaller models of watermakers draw their power from a large battery bank as DC current or from an inverter as AC current. Larger yachts typically run their watermakers via belt drive, which is the most energy-efficient method.

DC-powered desalinators are best installed to draw current from a large 8D battery bank, which in turn can be charged by a combination of alternative energy sources, namely, a solar panel array, a wind generator for use while at anchor and a water generator to be deployed while underway.

AC-powered models draw their power from either a DC-to-AC inverter or a generator. Some larger yachts use a small generator in place of a belt-driven system for the watermaker and other onboard systems in order to save fuel and wear and tear in the main power plant.

An engine-driven watermaker is the most efficient way to keep the water tanks topped off because there is no power lost in converting mechanical energy into electricity. Although this robust type of installation is generally seen only on yachts larger than 60 feet LOA, there are a few engine-driven units designed for smaller yachts as well.

Quality of construction

Before you invest your hard-earned dollars in a watermaker, review construction details, particularly the materials used in the manufacture of each unit you are considering. Some models rely heavily on inexpensive plastic parts, even for components under high pressure during operation. Plastic does reduce weight, making installation easier than with heavier materials, but be sure to research the comparative safety records of different models before making your selection.

Watermakers using bronze and stainless components in their construction tend to be more solidly built. However, crevice corrosion in stainless parts under pressure theoretically can cause rupture or even an explosion after several years of exposure to saltwater. On the other hand, high-quality, marine-grade bronze parts can be expected to last trouble-free for decades.

Some literature on marine watermakers suggests a quality disparity between open- and closed-frame construction. Some argue in favor of open-frame approach, which allows you to inspect the various components of a given unit at a glance so you can spot small leaks and component failure before total disaster ensues.

On the other hand, some industry experts suggest having a closed frame keeps internal parts safe from dents and puncture. Also, a closed frame permits gauges and switches to be mounted conveniently on a front panel for ease of use and monitoring. As long as panels can be removed for periodic inspection, common sense dictates they should be of little concern.

Before taking the plunge, gather all the information you can find on a given range of makes and sizes of units, and do your due diligence in researching competing models. Finally, make the decision best fitting your boat’s allowable space, the available charging source and your wallet.

Choosing the right watermaker

On a typical cruising vessel of anywhere from 35 to 60 feet LOA, a 12- or 24-volt DC watermaker system is probably the best choice. This allows a wider range of installation options, since the unit does not need to be close to the main power plant.

Sea Recovery, a subsidiary of Parker Hannifin, offers a wide range of watermakers capable of running on both AC and DC and covering the full gamut of yacht size. At the humblest end is the NFM model, which is housed in a small box to be mounted on a bulkhead with a pair of screws.

The smallest model in the NFM series, the AM 170, produces 7 gallons of fresh water per hour (GPH), or 170 gallons per day (GPD). At the top of the NFM range, the AM 750 produces 31 GPH, or an impressive 750 GPD. That’s a lot of water from such a small device.

Sea Recovery also offers 11 ranges of watermaker models larger than the NFM line. The Aqua Whisper Pro series has a range of surface-mounted units specifically targeted to mid-size and larger offshore sailing craft. Model 450-1 produces a modest 19 GPH, or 450 GPD, while at the top of the scale, the 1800-2 yields 75 GPH, or 1,800 GPD.

PowerSurvivor, a division of Katadyn in Switzerland, produces a wide range of watermakers, beginning with their humble, hand-powered Katadyn Survivor 06, which is small and light enough to fit in a cruising kayak. The Survivor 06 is Coast Guard-approved as an emergency survival device. This is a good thing to carry in your ditch bag, regardless of the type of permanent-mount watermaker you install.

The entry-level PowerSurvivor system is the Spectra Ventura 150, which runs on either 12 or 24 volts DC. This unit produces 6.3 GPH (150 GPD), more than enough for the average cruising boat. Weighing 60 pounds and running on either 12 or 24 volts DC at 4.5 amps, this unit is relatively easy to install and maintain. Since the unit consists of several main components, it offers a bit of flexibility in installation.

PowerSurvivor’s cruising selection of watermakers ranges from the Daily Cruiser 30 GPH Water Maker to the Spectra Newport 700 MKII Z for large power and sailing craft. The Daily Cruiser can be configured to be engine driven or powered by an AC source.

At the top end of the line, the Spectra Newport produces 41 GPH/1,000 GPD and runs on 24 volts DC or 120/240 volts AC. Though lower temperatures are known to inhibit the reverse osmosis process, PowerSurvivor boasts their watermakers are “designed to operate efficiently from the Arctic to the Equator.”

The Swedish company Dometic, known for its wide range of recreational and marine appliances, offers a unique selection of high-end desalinators through its Sea Xchange product line. What sets these watermakers apart from the competition is a digital, fully automatic freshwater management system which you control by way of a color touch screen. Each model offers NMEA 2000 connectivity, allowing you to control the unit from your chartplotter.

If you have a mid-size or larger vessel, look into the Sea Xchange models, which are designed for your convenience and ease of use. If you want a completely self-tending unit, consider the XTCII series watermaker, which automatically adjusts for variable water conditions, such as salinity and temperature. This series is available in four sizes ranging from 600 to 2,200 GPD.

To save a few bucks on this investment, consider instead the SXIII watermaker series, which permits you to adjust settings manually for changes in sea water conditions. This series is available in five models with the same size range as the XTCIII — 600 to 2,200 GPD.

FCI Watermakers of West Valley City, Utah, manufactures 15 models of marine watermakers, from the small, economical 200 GPD Aqualite to their largest model, the Atlas+APC/DTS, a commercial model providing up to 150 GPH, or 3,600 GPD, enough to fill a small swimming pool.

The Aqualite runs on 120 volts AC, provides more water than most yachts can possibly use on any given day, and is surprisingly compact, measuring only 20” deep x 28” wide x 11” high, not including electrical and hose connections.

In order to get optimum performance from the Aqualite, you can install an AQ3 Remote touch pad, which allows you to receive data on water quality, temperature, pressure, flow (GPM) and run time. This handy interface also allows you to turn off the Aqualite when required for servicing the unit.

A good choice for larger yachts is FCI’s Aquamiser+ Framed or Aquamiser+ Modular, both of which produce 250 to 1,800 GPD, more than enough for the demands of most yachts. The Framed version houses the entire unit inside a metal box, while the Modular version leaves major components exposed for easy access and servicing. Offered as “traditional” watermakers, both models have analog pressure and flow meters and a “fully automated programmable fresh water flush system.”

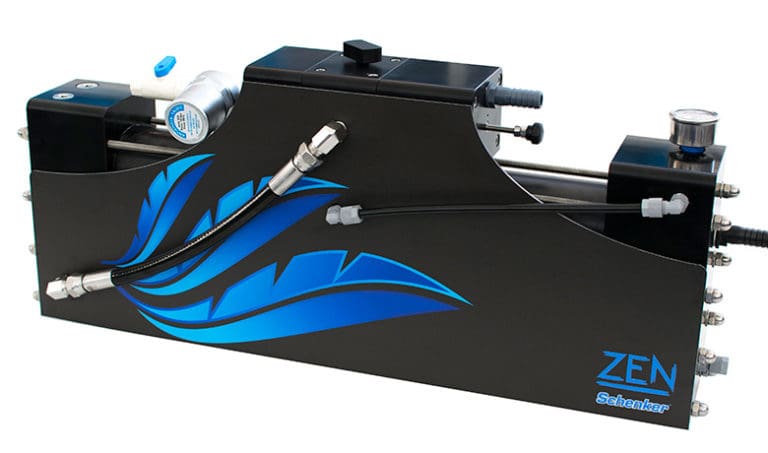

If there is a manufacturer out there listening to the pleas of humble sailors for a compact, modestly priced, easy-to-use desalinator, it is Schenker Dissilatori of Naples, Italy. Three design levels—Zen, Smart, and Modular—comprise Schenker’s line-up, each one offering a range of units with several levels of output.

Zen, the entry-level desalinator series, covers the freshwater needs of most cruising craft, offering outputs of 8 to 40 GPH, depending on the model. The Zen 30, which produces up to 190 GPD, is sufficient for sailing vessels of 30 to 40 feet with crews of one to four members. This model consumes 110 watts of power at 12/24 volts DC, allowing it to run straight from the house battery.

The Zen 50, developed for yachts ranging from 35 to 45 feet, the bulk of the world’s offshore cruising fleet, produces 50 GPH/1,200 GPD, far more than the average offshore yacht will need, even with each crewmember taking a shower every day. The Zen 30 is very competitively priced at roughly $5,600, and the Zen 50 at about $6,700. For much larger vessels, Schenker’s watermaker line proceeds through two higher levels of products, the Smart and Modular series.

If you are looking for a portable emergency desalinator, you need to check out the Schenker Aquatrek 30, which is capable of producing 7.9 GPH and is housed in a tough, military-style, wheeled box about the size of a medium suitcase. This small, portable device draws its power from a lithium battery and may also be connected to a 12-volt battery for operation and recharging. If you desire an economical array of high-quality watermakers, Schenker Dissilatori can definitely can produce an option that is “molto bene!”

Notes on installation and maintenance

Among the items included with a new watermaker will be a set of instructions laying out the process of preparing the necessary space, installation platform and access to DC, AC or engine power, along with diagrams for electrical wiring and through-hull connections. Before you embark on this process, though, it would be wise to undertake some of the planning and advance work in order to ensure a satisfactory installation.

If there currently is no obvious place for a watermaker in your vessel’s cabin, draw a rough sketch of where you expect to install the new device. In your diagram, include paths of wiring and hoses, ensuring any new through-hulls, if needed, are well below the waterline and, in the case of the intake hose, not directly downstream from the holding tank discharge port.

Ideally, you should be able to access and remove such parts as hose connections, filters, pump assemblies and electrical components as needed for servicing, repair or replacement. Also ensure you have an unobstructed view of all gauges and indicator lights.

Another advisable detail is to place the whole installation in a waterproof tray to catch dripping water or the occasional small part falling from the desalinator assembly. If an installation platform already exists, build a 2-inch-high lip, or border, around the edges of the platform and seal it with fiberglass and epoxy resin. This will ensure loose parts are not lost and small amounts of water do not seep down onto the cabin sole.

Finally, follow a strict maintenance schedule as detailed in the product literature. There should be instructions with timelines regarding the changing of filters, inspection of hoses, testing of freshwater quality, verification of proper pressure as indicated by gauges and so on.

By following the maintenance schedule included with the product literature, your new watermaker should provide you with many years of fresh, clean water with only a modicum of regularly scheduled operator maintenance. Happy cruising! n

Circumnavigator-author Bill Morris believes the best strategy for succeeding as an offshore voyager is to keep systems simple and, if possible, manual. Key to survival are a windvane self-steering system, a basic array of electronics and amenities, plus an aggressive alternative energy battery charging matrix. Bill is a frequent contributor to Ocean Navigator and the author of The Windvane Self-Steering Handbook (International Marine, 2004); Sun, Wind, & Water: The Essential Guide to the Energy-Efficient Cruising Boat (Seaworthy Publications, 2017), and The Captain’s Guide to Alternative Energy Afloat (Seaworthy Publications, 2019).