New battery chemistry means new ways of tracking system status

Having owned seven sailboats over the past 40 years, I have seen a few electrical systems. And over the past 14 years we have been on this cruise, I have seen a few more. And one of the key elements of a good voyaging boat is being able to monitor the vessel’s electrical system accurately

As a young US Navy lieutenant stationed in Guantanamo Bay, Cuba, in the mid-1970s, I purchased my first sailboat, a 1929 35-foot wooden Alden yawl named Cynara. There was not much of an electrical system aboard and not much need for monitoring devices. The two flooded lead acid (FLA) automotive batteries were there only to start the engine and power the navigation and a couple of interior lights. There was no refrigerator, water maker, inverter, radar, autopilot, chart plotter or other modern electrical devices. The batteries were charged with an old automotive generator belted to the Gray Marine gasoline engine. I monitored their voltage using an analog multimeter. This made for a pretty simple electrical system. It was a very basic sailboat, but did somehow take us from Guantanamo Bay, Cuba to Port au Prince, Haiti and back, once.

Our current boat is an electrically sophisticated 2004 44-foot St Francis catamaran with a plethora of modern electrical and electronic devices, all powered from our new LiFEPO4 (LFP) lithium battery bank. We have even recently started using an induction cooktop rather than our propane stove burners. A large solar array does almost all of our charging in the tropics. All of this requires a significant amount of energy both coming to and going from the battery. Careful wiring and a significantly upgraded monitoring system are required so that the lithium cells get neither over charged nor depleted to the point that they are damaged.

Since neither my wife Sherry, nor I are degreed marine electricians, the learning curve was steep. But luckily the COVID protocols here in Southeast Asia provided sufficient non-cruising time to study what to do, make necessary wiring changes, and add necessary equipment. I was able to add a few new tools to my already substantial inventory. Sherry was able to use her computer programming skills to greatly improve our electrical system monitoring display so that even I could understand what I was looking at. And we can now monitor it from anywhere in the world!

Battery chemistry important

Much of the reason for monitoring a boat’s electrical system has to do with providing safe charging and discharging of the batteries. Normally lead acid batteries need to be charged to 100 percent state of charge (SOC) almost every day, and they need to be discharged to no less than 50 percent. Every few months flooded lead acid (FLA) cells and sometimes other lead acid types, need to be equalized in order to reduce plate sulfation, shedding, and electrolyte striation. And, of course, FLA batteries need constant refilling of the cells with distilled water and can potentially release dangerous gasses if overcharged.

Deviating from these basics will negatively affect a lead acid battery’s service life. So, charging using modern equipment, and monitoring voltage and SOC according to the manufacturers’ recommendations for these batteries is very important. This is normally done using charging devices capable of three-step charging and monitoring equipment capable of reading voltages and amps to one hundredth of a volt (.01 v).

The relatively new LFP technology has a completely different set of charging and discharging requirements. LFP batteries no longer need daily full charging to 100% SOC, and actually do better with something less than that on a routine basis. LFP batteries can also be discharged safely to near empty without harm. This means not only can you use almost all of the LFP battery’s total capacity, but a full daily charge is not necessary. In order to ensure the safety of these batteries, however, the voltage of each individual cell making up the battery must be monitored and controlled at the millivolt (.001 v) level. So, in addition to a charging regulator that can monitor and control charging based on the total battery voltage, a battery management system (BMS) that can monitor and control charging based on individual cell voltages is necessary.

A proper BMS can safely disconnect the charging source in case of a high voltage event or disconnect the load in case of a low voltage event. Some BMSs disconnect the battery from the charge or load busses, which if not executed properly can cause problems. The BMS is monitoring individual cell voltages and performs its function if just one cell goes too high or too low. In the case of LFP cells a cell going higher than 3.650 volts or lower than 2.500 volts can suffer permanent damage. Thus, the lithium battery BMS becomes both a very precise monitor and a safety disconnect device that acts independently of any charging regulator.

Equipment

Typically cruising boats will have some or all of these charging devices like solar panels, engine-driven alternators, diesel or gas generators, wind or water generators, and shore chargers. The purpose of these is to charge the battery on a daily basis up to the battery’s total voltage set point on their regulation equipment. The accuracy and reliability of the regulators to precisely determine when to start and terminate the charge depends largely on the age and construction of the equipment and whether or not there is a voltage sensing wire to the battery. Older, less expensive regulators use the large charging wire for determining battery voltage rather than a dedicated more accurate small sensing wire. This can cause fluctuations in voltage as the current changes in the charging wire. An accurate multimeter can help facilitate precise adjustment of charging set points if necessary.

LFP systems often use the charging regulator to terminate the charge based on total battery voltage and the BMS to terminate if one cell’s voltage goes too high. Both parameters should be viewable on a good LFP monitor. Older monitors such as our Xantrex Link 2000 are able to monitor only total battery volts, amps and amp hours.

Heavy lead acid battery AC and DC loads are normally shut down by the boat owner as the house battery reaches near 50% state of charge (SOC) or an appropriate voltage. LFP house battery loads can also be shut off this way or the BMS can be set to disconnect loads automatically at any voltage or SOC. Modern quality BMSs are usually pretty accurate to the millivolt level so using the BMS is the preferred method for LFP batteries.

If you’re uncertain as to the accuracy of equipment to read battery voltage, a quality multimeter can be purchased. We use a UNI-T 61E, which we have compared to a high-end calibrated Fluke. It is within two millivolts over most of the range between two and 14 volts. With this it is possible to adjust the set points on all our electrical control and monitoring equipment.

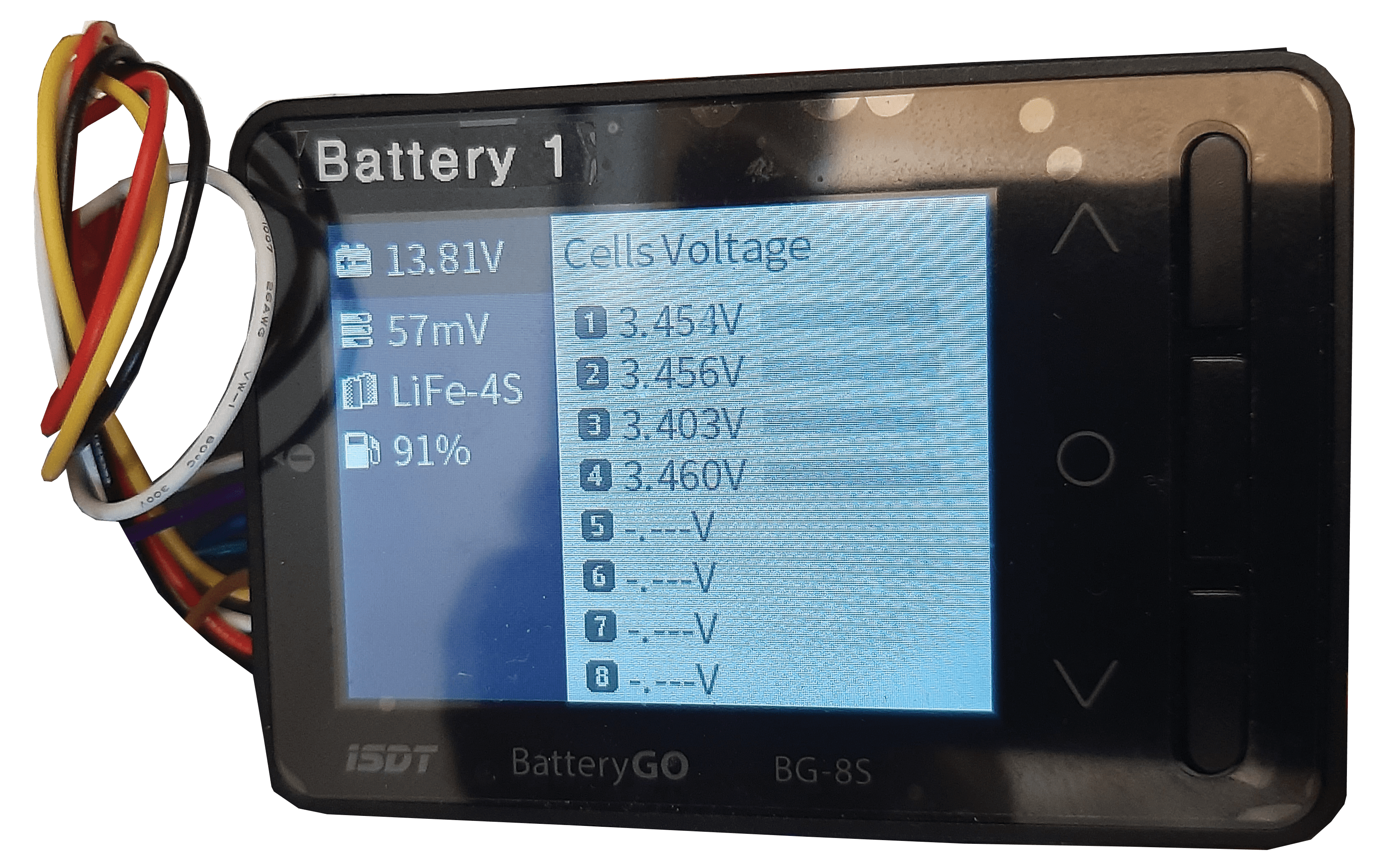

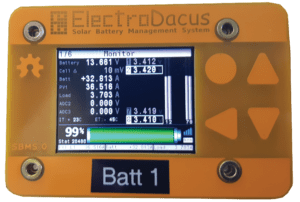

Other ways to measure voltage and current are the common automotive and marine analog volt and amp meters often seen on engine instrument panels. These give convenient but rough electrical system data at the helm station while underway. There are also many small and inexpensive digital devices offered for sale on the Internet. Before our Electrodacus solar battery management system (SBMS0) arrived we used a couple of these, including the well regarded ISDT BattGo BG-8S monitor/voltmeter/balancer. We also used a small digital timer and a Hall effect current sensor to estimate the daily amp hour usage of our refrigeration systems. All of these can be mounted permanently for a quick visual check of equipment status. Some of these could be used in place of a more sophisticated, and expensive monitor, but capability and accuracy will probably suffer.

Many modern boats have integrated electrical systems installed using quality equipment that can display data on a NMEA 2000 network. Some well-known companies like Mastervolt, Xantrex, Blue Seas, Newmar and a number of others cater to the LA battery charging and inverter market. But few companies other than Victron have charging, monitoring, control and inverter systems that are designed to work and communicate well with LFP systems. Highly accurate, quality BMS’s from companies like Orion, REC, Electrodacus and Victron, function well with LFP batteries.

Most BMS’s are designed to use Bluetooth technology to display local monitoring and control functions to a mobile device (smart phone or tablet). Some inexpensive BMS’s, however, lack both display accuracy and functionality. Our Electrodacus SBMS0, made by a small company in Canada, has a WiFi display option rather than using Bluetooth. With the right software, both WiFi and Bluetooth connections can be funneled into a laptop or Raspberry Pi device running monitoring software. Once on a laptop/Pi, and with the proper software, the data and status can potentially be accessed via an Internet connection even when off the boat. Likewise, some BMS’s are starting to support NMEA 2000 connections, so battery status can be monitored via newer chart plotters and multifunction devices.

For onboard monitoring nothing beats what can be done using open source software such as Node Red and Influx DB/Grafana to build a custom monitoring and logging system. This software allows a user to build a display with not only numerical data but also sophisticated graphs and charts. They are infinitely customizable and able to be exported to a number of mobile devices for display. Our SBMS0 exports data wirelessly to our computer using Wifi, and it has a logging capability that logs desired data every 10 seconds and can store that data for many months.

Wiring

In order to properly control and monitor a boat’s electrical equipment the owner should have a thorough understanding of the system. In order to understand a system fully, a wiring diagram is a useful tool that will be very helpful should something go wrong. This is especially true if a marine electrician that is not always on the boat is involved. Properly done, charging system wiring should be kept separate from load wiring. This means two separate buss bars, where all charging source wiring is routed to the charging buss and all load wiring to the load buss. Some boats use a third buss for critical system equipment like bilge pumps, radios and autopilot.

The purpose is to be able to shut down one buss without affecting the others as in disconnecting the charging buss from the house battery without affecting the loads. This is particularly important when using some less capable BMSs with internal Mosfet relays that separate the battery from the buss rather than using external relays to turn off the source equipment.

It is also important not to disconnect the battery from an alternator or solar regulator while they are under full charge. It is much safer to just turn off the equipment and leave the battery connected to the buss. Most external regulators will do this automatically, but it is worth monitoring this function initially lest there be a gremlin in the wiring.

In addition to the above, careful attention needs to be paid to wiring of fuses, sensors and shunts. Fuses will protect your circuits from a short should you not be watching your monitor. Proper installation of sensors and a separate sensor wire for equipment reading battery voltage will ensure better accuracy. Shunts allow current monitoring. Using two shunts will allow monitoring of charging current, load current and net current into the battery. Being able to see all three of these values is very useful. Most quality BMS’s and earlier electrical monitors can take the current reading over time and display the result in amp hours. Many less expensive monitors calculate SOC using voltage, which for LFP batteries is too inaccurate.

Some cruisers we know prefer not to monitor their electrical system performance on a daily basis, instead relying on their equipment to perform properly. For most of us having to turn on a mobile device to monitor electrical system function several times a day is not much of a burden. Given the sophistication of today’s electrical and electronic devices, and the fact that we are operating in a marine environment, we think it is prudent to routinely keep track of system performance. The trick is to make the monitor display easy to access and read. Most monitoring at the cruiser’s level is not proactive and relies on someone taking some action. Setting known thresholds on BMS systems can offer considerably more protection by shutting things down before damage occurs. An alarm sounding before a shutdown is a worthwhile addition.

We now use a modern, current efficient computer running most of the time we are on the boat. Some use an old spare Android phone or tablet. Besides giving us a ready monitor display, it gives us quick access to weather, navigation tools and anything else we want to leave up.

a custom display.

Soon we will incorporate a small Raspberry Pi device running Mosquitto Broker, a Node Red system, and our custom display. A Raspberry Pi is essentially an inexpensive, but very capable small computer, that can function well for a number of things including as a monitor. This will significantly reduce the current draw of our monitor compared to a standard Windows laptop computer. With a little more effort, one can expand the Raspberry Pi monitoring to include cycle times and temperatures for such equipment as refrigerator compressors, bilge pumps, freshwater pumps and engines. By using thresholds you can then make it proactive so it tells you when you’re not looking. For example, it can tell you that the freezer compressor has run 24 hours straight!

By paying close attention during the installation of new electrical and electronic devices onboard and monitoring their performance while cruising, you will hopefully not experience one of those “lights out” events that cause discourse among the crew. Also, the engineer can add a few new tools and the crew a few new electrical luxuries. This is one time a few minutes spent on the smart phone or computer on a daily basis is worthwhile for something other than perusing social media. ν

Dave McCampbell is a former US Navy officer who spent most of his time as a diving and salvage oifficer. He commanded the Rescue Salvage ship, Bolster and two shore-based diving commands. He and his wife Sherry voyage aboard their St. Francis 44 Mark II Cat Soggy Paws.