Having taken us two and a half years to build, we had just launched our 36-foot carvel-planked cutter when the bad news hit: a hurricane had formed and was quickly heading our way, targeting the area where our boat was berthed. Since the marina would have little to no protection from the wind and storm surge, we had to get this engineless boat up river, anchor, and then, with no ands, ifs or buts about it, stay put.

We had already purchased our storm anchor, a 70-pound Luke (fisherman-style) anchor, and our main bower, a 50-pound SuperMax anchor, as well as a spool of 5/8-inch nylon three-strand rope, the size that the rope usage charts indicated was best.

We also wanted some chain, something that at the time of launch we thought that we had plenty of time to obtain. Instead, we ended up having to rush around and, finally, at the last minute were fortunate to find a drum of chain of a size adequate for the upcoming conditions.

We say fortunate because, since then, time after time, we notice that as soon as a hurricane or storm warning is issued much of the heftier gear quickly disappears from shelves. Because of this phenomenon it’s good to get all necessary gear early, months ahead of time, particularly if it has to be ordered.

In spite of our high anxiety as first-timers anchoring in harsh conditions, we didn’t drag nor did we break free. Although we were using rope of the recommended size, we were alarmed at the severity of tautness that developed in our nylon rode and snubbers.

In spite of our high anxiety as first-timers anchoring in harsh conditions, we didn’t drag nor did we break free. Although we were using rope of the recommended size, we were alarmed at the severity of tautness that developed in our nylon rode and snubbers.

This tautness concerned us for two reasons: The first is chafe. Even with the use of anti-chafe techniques rope can still find a way to chafe, and with rope this taut, chafe would progress rapidly. The second is heat. Due to surge loads, rope stretches and relaxes causing its fibers to rub against one another and this creates heat. Even keeping the rope wet to lubricate and cool it this heat can reach the point where the fibers melt.

As we kept our eyes on our rodes and snubbers, we couldn’t help but think that there had to be a better way to size rope. As we looked for answers, we discovered two things: One, the chart sizes, though unstated, are usually for milder weather; and two, the better way to size rope, whether for rodes, snubbers or bridles is to choose rope based on the following three criteria, and the harsher the weather, the more critical these three criteria become:

• A minimum of eight percent stretch at 15 percent loading. This amount of stretch, and usually more, is found in nylon three-strand, eight-plait, and twelve-braid rope.

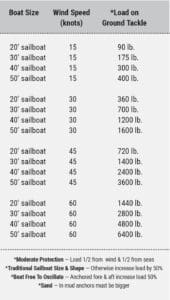

• Tensile strength of at least eight times that of the highest load. Loads can be determined by consulting a load table, such as the one provided in this article. Once the load has been determined, consult the rope manufacturer’s sizing chart and cross reference this tensile strength to the size rope with this strength.

• Long stretch-length. In calm conditions, even a short length of line may be adequate to cushion surge loads since little stretch is required. But as conditions worsen, lines that will be involved in cushioning surge loads need to be longer — for gales at least 30 feet, for storms at least 40 feet, and for hurricanes even longer. A ten-foot line with ten percent stretch will stretch one foot; the same line, 40 feet long, will stretch four feet, a huge difference in the longer line’s ability to cushion surge loads.

What is critical, especially in harsh weather, is not stretch per se, but whether there is adequate reserve stretch, the stretch that remains in the rope after the wind has taken its share of stretch out of the rope. It is this reserve stretch that cushions surge loads, the loads created by wind gusts, waves and seas.

If adequate reserve stretch is absent, then the ability to cushion surge loads is poor, maybe even absent, risking chafe, melted fibers, and shock loading. Studies have shown that even mild shock loads will easily double or triple the load.

It is having adequate reserve stretch that is the goal sought by sizing rope to all three of the above criteria. Counterintuitively, these larger lines will also provide sufficient stretch in light conditions; plus, larger lines are more resilient to chafe and melting.

Overloading nylon rope has a third danger: exceeding 15 percent of nylon rope’s tensile strength increases damage to the rope’s fibers and the greater the load or the longer the load exists the greater the damage, damage that is cumulative and permanent. For example, shiny surface fibers or little hard nodules on surface or inner fibers of a nylon rope indicate that those fibers had gotten hot enough to melt. With this damage the rope no longer has its rated strength and consideration should be given to retiring the rope from use in the boat’s heavy weather plan.

When it comes to using rope in a rope/chain gypsy, the rope is usually sized to be twice the diameter of the attendant chain. But the unspoken caveat here is that the size rope that is specified is rope made to the Cordage Institute standards. (The Cordage Institute’s standards, and a list of member manufacturers who adhere to them are available at www.ropecord.com.)

If you choose non-institute compliant rope, be forewarned that in order to achieve its stated tensile strength, the rope may have had to be manufactured to a diameter larger than that found in the Cordage Institute standards. This doesn’t mean that non-institute compliant rope, if it has the necessary tensile strength, cannot be used elsewhere, it just means that it may not work in your rope/chain gypsy.

Conversely, if a rope does work in your gypsy, it may not, especially for harsher conditions, conform to the three criteria listed above. If it doesn’t, switch to a line that does, even if it requires deploying and retrieving the ground tackle by hand or using other gypsy-less methods.

As to snubbers or bridles, we advocate always installing one or the other, as: 1) adequately sized, they cushion surge loads; 2) once the rode is slacked off, they remove the load from a windlass’ mechanism, thus protecting that mechanism from damage; and 3) when used with a rope rode, they save the rode from chafe. n

Rudy and Jill Sechez are the authors of Anchoring, A Ground Tackler’s Apprentice, available as hard copy or e-book, and coming soon, an app, any of which are available through Waterway Guide.