Preparing a vessel for an offshore passage encompasses many tasks, from installing safety equipment to doing a rigging inspection. One area that tends to get overlooked in many preparations is the boat’s rudder and steering system. Often these systems are taken for granted and, if checked at all, given a cursory inspection.

Because offshore sailing places large stresses on boats and gear, it is important to plan for the unexpected. Offshore help, if available at all, is often days away. If a boat is completely incapacitated offshore it will often have to be abandoned, as recovery may be too difficult or costly.

Every year a surprising number of offshore boats are abandoned or lost because of steering problems. The forces placed on the rudder and steering system as the boat pitches and rolls in the seas is tremendous. This is why proper rudder and steering inspection is so important.

Once offshore it can be very difficult or impossible to make repairs to the rudder or steering system. If the failure is in the steering mechanism, the rudder will likely still be moving back and forth in the seaway. Many parts of the steering system will be moving along with the rudder. This will make doing any work not only difficult but dangerous, as suddenly moving parts can easily trap a finger or hand. Problems with the rudder itself are often not repairable at all while at sea.

Two basic types

Steering failures fall into two basic types: loss of control of the rudder, and loss or failure of the rudder itself. Loss of the rudder can consist of the rudder breaking off at the shaft and sinking or floating away, or the internal structure of the rudder failing and thereby allowing the rudder to spin freely on the shaft. Most fiberglass rudders are formed over an internal metal framework. If this framework breaks loose from the shaft, the rudder blade will no longer work to steer the boat. The rudder can also become jammed in a position that will not allow it to be turned. This last situation is perhaps the worst as the rudder is usually jammed with the boat in a hard turn, making it difficult or impossible to overcome this turning force with an emergency method. This is often a result of a rudder stop failure allowing the rudder to be turned further than designed.

|

|

A rudder with a failed lower bearing. |

Although losing a rudder is one of the most problematic and difficult situations to overcome, few owners properly inspect their rudders prior to leaving port. This is partly because to properly inspect the rudder and its parts, the boat needs to be hauled out. In many installations the rudder also needs to be dropped to inspect the shaft, bearings and other fittings. For anyone planning an offshore passage it would pay to spend some time inspecting the rudder during an annual haul-out prior to a passage. A quick visual inspection can reveal possible problem areas before they become larger problems. A few key areas to look at are the condition of the rudder itself, as well as the rudder shaft and any bearings and supports.

First, inspect the rudder for damage or anomalies. Look for any bulging on the rudder sides as well as any water and rust weeping from the rudder. If found, this may indicate internal problems. Fiberglass rudders are made in two halves sandwiched over the shaft and internal metal framework welded to the shaft. Check the center seam of these two halves for cracking or splitting, or anything that does not look right. Moisture inside the rudder can cause corrosion to the welds holding the metal frame to the shaft. If problems are noted, it may pay to have a professional look at it. Moisture meters can reveal problems as well as “tapping out” the laminate to check for delamination.

Next, grab the rudder by the trailing edge and move it side to side. Note any play or sloppiness. With the helm free to move, push the rudder along its full travel port to starboard and back again. Note if it does not move smoothly or has any hard spots. See how it feels when it hits the end of its travel at the stops; does it come to a nice full stop, or does it feel mushy? Make a note of anything that does not “feel” right, as you will want to investigate the cause later. Next, with the helm centered, hold the rudder on the bottom edge and firmly move it side to side. There should be little to no play. If there is play, watch the bearings for movement both within the bearing and the bearing itself in the hull. Have someone watch the upper bearing where it attaches to the hull and note any movement. Next look at the shaft where it enters the hull; the gap may be too small to see anything, but if some of the shaft is exposed try to clean any bottom paint from it and look for pitting, corrosion or wear. Finally, with the rudder centered, step back a few paces and sight the shaft to see if there is any sign that it is bent. If it looks to be bent, it will pay to check things more carefully.

It’s a good practice to remove the rudder every five years or so for a complete inspection. Most catastrophic rudder failures occur when the shaft simply breaks off and the rudder falls away. With newer designs using spade rudders with no lower or mid support, this becomes an even greater concern. A great deal of bending stress is placed on the rudder shaft right where the shaft enters the lower hull bearing. Add to this the fact that this area is subject to a harsh corrosion-inducing environment and you have a possible weak spot. This area of the shaft is exposed to damage from marine growth, seasonal cleaning, bottom paints, as well as wear so careful inspection is important. Dissimilar metals nearby can induce galvanic corrosion as well, and few rudder shafts are properly protected. Inspect the whole shaft but particularly in the area where it enters the hull. Clean the shaft well and use a magnifying glass to examine it. It is critical to make sure there is no pitting or crevice corrosion as this is what leads to sudden failure in metal shafts. Fiberglass shafts should be inspected for stress cracks or light colored streaks. If the shaft is hollow, a borescope should be used to inspect the inside of the tube if possible.

Bearing inspection

With the rudder and shaft inspected, it is time to check the bearings. Most boats use glide bearings for the rudder shaft. Glide bearings are simple sleeves made of high-density plastic, rubber or sometimes bronze. The rudder shaft turns freely inside the fixed glide bearing. With this type of bearing you want some play between the shaft and the bearing to allow water to lubricate the bearing. Glide bearings can last many years and only need replacing when the play between the bearing and rudder shaft gets excessive. In older boats these bearings are sometimes bronze, particularly with a bearing on the bottom or heel of the rudder.

|

|

A small but effective emergency rudder pressed into service after complete loss of the vessel’s rudder. |

Newer high-end and racing boats will often use roller bearings. Roller bearings should be replaced every five to six years whether a problem is indicated or not. All bearings tend to wear out over a period of time but, when roller bearings fail, they can fail catastrophically causing a loss of steering — or worse, failure of the rudder seal as well.

If the boat has a skeg or a keel that extends aft to the rudder, there may be a mid or bottom bearing as well. These need to be checked as rudders can fail due to a lower bearing giving way. Rudders with lower bearings will usually have smaller shaft diameters that will not be able to withstand the forces of supporting the whole rudder should the lower bearing fail. These lower bearings are subject to high stress and can be damaged by groundings that may not be immediately apparent. Often these lower bearings and supports are coated in heavy layers of bottom paint, making inspection difficult. If this is the case it is wise to fully remove the paint and clean the parts for inspection. Check for play in these bearings as well and, if found, it may be time for replacement.

Once the outside of the rudder has been fully inspected it is time to move inside the boat. Visually inspect where the rudder shaft enters the hull. Check the shaft seal or packing for signs of leaking. With a traditional flax packing stuffing box, if a leak is noted you may be able to just adjust the packing nut. If it has been more than five to six years since the last repacking it may be a good time to do this, as this type of packing tends to dry out. If the seal is a more modern dripless type it is important to note any leaking as well. If leaking is noted, the seal should be replaced. Some boats, particularly older fiberglass boats, will just have a tube extending above the waterline. If this is the case, inspect the tube for cracking or damage and check any supports.

It is also important to check the upper bearings and bearing supports. As the upper bearing is not in the water it is often an off-the-shelf pillow block type bearing. In installations where a tube glassed into the hull is used, there may be a glide bearing installed inside the tube. Have someone outside the boat wiggle the rudder back and forth while watching the bearing and supports for play or movement. The upper bearings take a fair amount of load, particularly in spade rudders with no lower support, so it is very important to make sure the upper supports are in good shape.

Inspect the supports, making sure there are no signs of movement. If the supports are glassed in, carefully inspect for loose tabbing. Many supports are metal-bolted to other structures. If metal, inspect for corrosion and check all the bolts and make sure they are tight. Check any support structures for cracking or rot in wood. If the supports do not look robust enough, consider adding some additional support. More than one boat has been lost when the supports for the upper bearing came loose, allowing the rudder shaft to pivot in the lower bearing to the point where it ripped the lower bearing out of the hull.

Check the quadrant or tiller arms as well. Make sure it is tight on the shaft and appears to be in good condition. Look for cracks in the casting and make sure all the bolts securing it are tight. There should be a keyway with a key in the shaft to prevent the quadrant from slipping on the shaft. Some may have a pin through the shaft but a keyway is the preferred method. Make sure any pin or key is in good condition and not bent. If no key or pin is used and the only thing stopping the quadrant from turning is a set screw, you may want to correct this. A set screw can slip or shear off, allowing the rudder shaft to spin free inside the quadrant so this is not an acceptable method of preventing slippage on the shaft.

|

|

Pitting in the rudder shaft can lead to sudden failure. |

Cables

Where steering cables are used, be sure to check the cable ends and fittings. It is common practice to use a threaded eye bolt to attach the cables to the quadrant. These eye bolts are also used to adjust the cable tension. Make sure the nuts are tight and that locking nuts are in place. Avoid the use of nylon lock nuts as these can gall when tightening and sometimes give the impression they are tight when they really are not. If the eye bolts are not welded closed and are just a loop bent into the end, they should be welded closed or replaced with a welded eye. Under heavy strain non-welded eyes can open up, freeing the cable. Check all bolts for tightness using a wrench. Inspect the cable where it is attached to the eye bolts and make sure it is not damaged or fraying. Inspect the cable clamps as well — these can and do come loose. If a ram or autopilot drive is fitted, check the end fittings and the bolts securing the end to the tiller arm. Look for any looseness or play. Finally check the end stops to make sure they are intact and solid. A failed end stop can result in over-travel and lead to damage to the steering system or rudder. Stops must be robust enough to handle the forces of a knockdown or grounding, and can be damaged by years of abuse.

Quadrant

While checking the quadrant, make sure there are no loose hoses, cables or wires that are contacting or close to any moving parts. If found, secure these away from the moving parts to prevent damage. Many rudder shafts and quadrants are located aft in a locker where equipment is stowed. If there is no cover over the moving steering parts, it would be all too easy for this equipment to become dislodged and end up jamming the steering. This is particularly true when sailing offshore. It is important to make sure equipment cannot contact any moving parts in the steering. If covers are not in place, it is easy enough to fabricate them or relocate the stowed supplies.

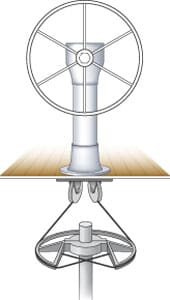

Steering system maintenance is important for a reliable voyaging boat. Watch the first in our series on steering systems. Hosted by contributing editor Wayne Canning and sponsored by Edson Marine (www.edsonmarine.com), this video shows you how to maintain your boat’s steering pedestal.

Cable pulleys and mounts

With the rudder, bearings, quadrant and stops fully inspected, it is time to start looking at the rest of the steering system. Start at the rudder and follow the system back to the helm. Check the condition of the pulleys and mounts. Make sure the supporting structures are in good condition and that all mounting bolts are tight with lock nuts. Once again check with a wrench to ensure they are tight. Inspect the steering cable using a rag to find fish hooks or broken strands. Check any pulleys for play; wiggle them side-to-side to make sure they are tight. Look for debris or filings just below the pulleys, as these can be indication of wear. Take the time to pull the pins in the pulleys to check for wear as well. If the pins are older bronze, it might be worth upgrading to stainless steel pins as these resist wear better. Use some spray Teflon grease to lubricate the pins and bushings. Never use WD40 or the like, as this will wash thicker grease out and leave little lubrication. Make sure the cable leads are fair and not binding or chafing on anything.

Conduit check

For systems using conduit cables, carefully inspect the ends that secure the conduit to the end fittings. These are often plastic and can become brittle with age. If these ends break it could result in loss of steering. Conduits should be replaced every seven to 10 years, as the cable will wear the inside of the conduit. If the cable wears through the conduit casing, it could cause the cable to bind and lock the steering in a fixed position. The conduits should be lubricated every year with Teflon grease.

Chain failure

Most steering failures on chain and cable systems occur when the chain or cable fail. This is often the result of poor chain maintenance or improperly adjusted cable tension. It is important to check and lubricate the chain in the helm at least once a year. If planning an extended or offshore trip, the chain should be fully removed for a thorough inspection. If older than seven to 10 years, this might be a good time to simply replace the chain. If keeping the chain, carefully inspect for corrosion, stiff links and seized rollers. It is important to carefully inspect stainless steel chains for pit corrosion as well. Small pits in stainless steel are an indication of larger problems and, if in doubt, it is best to replace. This is also a good time to inspect the chain sprocket. Look for wear and broken teeth. Once again — if in doubt, replace. Lubricate the chain and helm shaft bearing with T-9 Boeshield followed by some 30-weight motor oil. If the shaft bearings are needle bearings then Teflon grease should be used.

Pedestal check

When at the helm, it is a good time to check the wheel break, cable leads through the pedestal or helm, and the idler pulleys and plate at the base of the helm. The wheel break should be checked for proper operation, loose fittings and fasteners. With access to the top of the helm open, carefully inspect the break and its components. Makes sure there is no oil or grease on the pads and drum. Next use a light to look down into the pedestal, or open any inspection plates to inspect for wires or cables chafing on the chain or steering cables. Most modern helms have a fair amount of electronics installed, it is important to make sure none of these wires contact any of the steering parts. Go under the helm to check the lower idler pulleys and mounting plate. As most pedestals tend to leak some, this is an area subject to heavy corrosion. Check the mounting plate for corrosion — many builders use aluminum or steel for these and the salt water leaking down on them can have an adverse effect. Check the pulleys, pins and mounting bolts as well.

Lastly, the cable tension should be checked and adjusted. The cable should be adjusted just tight enough so that the quadrant cannot be moved with the helm locked on center. The cable should only be adjusted once the system is fully lubricated. Be careful not to over-tighten the cable; a little play is better than too tight. Too loose and the cable can jump off a pulley or quadrant, resulting in loss of steering. Cables stretch with use so they need to be checked often — particularly after a long passage and grounding, or a heavy weather use.

|

|

A worn chain in the pedestal can fail and if spares are not available, an emergency steering setup will be needed. Regularly replace key steering gear and have spares on board. |

With a fully mechanical or geared system, check the quadrant the same way as with a cable system. Turn the wheel and “feel” for any excess play. Carefully inspect every connection and joint, lubricating as you go. Make sure the connecting pins are in good condition and that they cannot come loose; if cotter pins are used, make sure they are secure. Check end fittings for wear and play as well. Many end fittings will have bearings in them and it is important to check these and replace if worn. Check any universal joints for wear and lubricate as recommended. Check any gears and bearings for wear as well.

Finally, check the helm itself for problems. The pedestal is securely fastened to the boat. If excessive flexing is noted, add backing plates. Helms should be capable of withstanding the force of the helmsman or crew being thrown or falling against it in a seaway. Make sure the wheel is tight on the shaft with little or no play.

A bit of preventative maintenance will go a long way toward keeping your steering system functioning properly.

Capt. Wayne Canning lives on his Irwin 40 Vayu, in Florida. A marine professional for more than 35 years, he is now a full time marine surveyor, freelance writer and consultant/project manager on major repairs.