You could argue that there are many “most important” systems on your trawler: diesel fuel delivery systems, firefighting systems, head and holding tank systems, electrical systems, etc. These are obviously all essential. Yet, there is one system that is often overlooked and should always be “on duty.” Bilge water is undesirable and, as such, your bilge pump system is critical. It needs to be ready 24/7 (whether you are aboard or not) and may need to be placed in service at a moment’s notice.

On an active trawler, the ability to empty unwanted water from inside your bilges should be considered a performance feature right up there with being able to stop (anchor), steer and run your engines. Your bilge water removal system isn’t as glamorous as your hydraulic, electric or diesel systems, but from a practical standpoint bilge pumps for safe operations simply cannot be ignored.

Dialing-in your trawler’s bilges starts with a few questions: How long has it been since you cleaned out your boat’s bilge? When was the last time you added some fresh water to your bilge to confirm your pumps are discharging? Do you have a “bilge boom” to absorb errant fuel and water?

Periodic maintenance and regular inspections, including practice flush runs, will confirm operational status. Don’t assume anything. Like most systems on your boat, regular exercise keeps the parts ready and will let you know if there is anything that needs attention.

My priorities when I board a trawler are to first go to the electrical panel to determine the status of battery voltage, and then to check the bilge level. I can relax after confirming there is power coming in and we aren’t sinking. Similarly, when I depart a trawler that will be away for an extended period, I confirm that the bilge pump breakers are on and that shore power is coming in to power the pumps.

Bilge pumps will evacuate all fluids, including oil and fuel. There are heavy fines for discharging diesel; any fuel/oil discharge from your trawler is an offense and the authorities only need to see fuel on the water surface to levy a fine. Check your bilge water (fuel and oil floats on the top) before activating a bilge pump. If you are going to leave your trawler in the water for a long period, I recommend you close off fuel sources (fuel tank sight tubes are especially vulnerable) to minimize the potential of spreading a sheen of diesel around your harbor. I would also suggest you turn off your freshwater system when you leave so that a leaking hose or fitting won’t fill up your bilge in your absence.

Do you have separate bilge areas or does it all collect in a deep sump? Some trawlers have isolated chambers divided by watertight bulkheads. With this arrangement, each compartment is typically fitted with an independent bilge pump. Other trawlers have limber holes (tubes or openings) that allow bilge water to migrate between sections (through stringers and bulkheads), which are often designed to drain aft into a deep bilge in the engine room or machinery spaces.

Some commercial ships and many high-end trawlers have a clearing chain that runs the length of the bilge through the limber holes. These chains are connected with a shock cord forward and a handle aft. You pull on the handle and the clearing chain softly scrubs the limber holes to dislodge obstructions. This is a project you might consider taking on.

|

|

A typical trawler bilge with pump, float switch, shoe and tide stick. |

Diagram your bilge layout

For you to understand your trawler’s bilge, you are going to need to explore and poke around by lifting up your floorboards to inspect your trawler’s nether regions. Diagram your bilge pump plumbing layout so you know how it is set up and where the moving parts are that may need servicing, and add a reminder to inspect each area regularly. Some manufacturers include a bilge schematic; use this to comprehend how your trawler bilge system drains from bow to stern. You need to know where it will all combine to become bilge water. I’ve seen trawlers that had moldy bilge areas tucked under forward cabin soles that the owner didn’t even know existed.

So, where does bilge water come from? If your trawler has a traditional flax packing stuffing box that allows seawater to enter through the cutlass bearing to cool the main engine shaft, then you will have a normal leak that will drip into the bilge. A few drips can add up to a measurable amount in a short time, and many stuffing boxes continue to drip when your trawler is idle. Air conditioning compressors develop condensation and often that is directed into the bilge (diverting to a boxed sump with pump will help contain this excess water). A leaky hose fitting from your fresh, sea, gray or black water plumbing can also increase the quantity of fluids in your bilges.

Oil drips and fuel leaks also use gravity to find their way into the lowest point and can contaminate your bilge. Absorbent pads (like those found in diapers) lined under your engine oil pans will soak up drips, making cleanup easier. Absorbent booms floating in your bilge will wick up much of these petroleum products, helping to clean your bilge water and making it easier to throw this mess away. Tie your booms within reach so that you can retrieve them when it is time to change them. Remember, no oil or fuel can legally be pumped overboard. Keep an empty five-gallon bucket and use a wet vacuum to skim it off the top then dispose of the contents at an oil drop station.

Check every hose and fitting to make sure they are secure, and monitor them regularly to ensure they are not leaking. I’ve seen trawler owners use pipe cleaners (furry wires for cleaning smoking pipes) wrapped around fittings to act as a telltale for leaks.

Locate through-hulls

It’s a worthwhile project to map out your through-hulls (the most common means for water to be invited into your trawler) from chain locker to swim platform. Since through-hulls are holes in your boat, they are a very common source of potential bilge water. Most through-hulls are always open but may need to be closed if there is a problem. You need to not only learn where they are located, but exercise them to make sure they are always ready to open and close. Double-check that hose-to-seacock connections below the waterline are secured with double hose clamps.

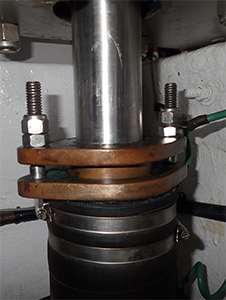

In addition to valves and seacocks, don’t forget all other hull penetrations as a possible source of outside water entering your vessel. Engine cutlass bearings, rudder shafts and active fin stabilizers all have seals to keep seawater from entering inside. Each of these have service and replacement intervals that demand your attention.

Bilge water

Bilge water can be nasty. It looks harmless and is normally a combination of fresh water and salt water. But since it is a collected pool of whatever liquids are captured, you really can’t be sure what it contains. Oil, diesel, coolant and even sewage can find their way into your bilges. I’ve seen a loose hose fitting result in the contents of a stabilizer’s hydraulic oil reservoir being dumped into the bilge! Knowing this, be cautious and definitely don’t ever taste bilge water to decipher what flavors are included. There is a very real story of a surveyor who casually dipped his finger into the bilge for a quick ID and woke up the next morning violently ill and was hospitalized with a major staph infection from a simple taste test.

|

|

A typical rudderpost, an often overlooked area for producing leaks. |

Removing bilge water

To just about every trawler owner I know, the goal of a dry bilge is heaven aboard. If you keep your bilges clean and dry, they won’t smell and you can more quickly identify a new mystery leak by following the trail.

This is where bilge pumps come into play. Think of bilge pumps as giant straws: They remove fluids through suction and are designed to convey bilge water overboard.

There can be a lot of force when pumps are running; hose plumbing needs to be stout so it won’t collapse. This also means that these stronger hoses are stiff and not as easy to work with. The diameter of the hose will influence how much water is processed, as will the length of hose and angle of the run from bilge bottom to top of the return.

Bilge pumps are designed to remove bilge water via an upward flow to a rising U-bend above the discharge port followed by a downward flow after the bend, dispensing the water via the exit through-hull. This typical up, over and down arrangement helps remove more water and minimizes back flow (the bilge water in the hose that does not make it over the bend at the top). There is usually some water in the suction hose that returns to the bilge when the pump stops. The longer the run, the more power is required of the pump to lift and dispense the bilge water.

Strive to keep your bilge water level low so it doesn’t slosh around where it can soak fittings that can corrode. On faster trawlers, when the bow rises at speed, bilge water will rush aft where it can splash and damage areas that shouldn’t get wet.

Wet bilge areas are moist environments and depending upon water levels, humidity and air flow, they are susceptible microzones that can develop foul smells, mold, condensation and rust.

Bilge pump pick-ups

Bilge pumps need to be sized to evacuate bilge water in proportion to the volume of bilge water expected in worst-case scenarios, and the math involved must take into account variables such as hose diameter and length to ensure your trawler does not become overwhelmed.

Often, there is a “shoe” attached to the low end or pick-up point of the bilge hose where suction is initiated. These shoes are designed to act as strainers to prevent large chunks (wood shavings, plastic, metal fasteners, etc.) from getting into the hoses. Bilge shoes look like a cheese grater on the underside. Many trawler builders affix these shoes to the bilge bottom so that they don’t shift around when the pump is chugging, but I prefer them to be moveable so that I can more easily access them to clean them off. If you have a moveable shoe, you can use a wet vacuum to clear off debris that gets stuck. It isn’t always easy to service a bilge shoe, but that’s no excuse to ignore one. Bilge pump hoses are stiff and the way they are routed usually restricts simple access, but you need to figure a way to inspect the shoe bottom — a mirror on an extension is one solution — to confirm the shoe isn’t clogged. Some trawler owners tie a plastic cord with a lasso around the shoe fitting so that they can lift it up with a strong pull to inspect the underside.

|

|

Long-reach grab tools can be invaluable for removing items out of deep areas of the bilge. |

Bilge water level

It is easy to tell how much bilge water is new in a shallow sump. For deeper bilges (more common on full-displacement trawlers), I’ve come up with a simple method to measure the level. I call it a “bilge tide stick,” and it can be an easy spare-time project for you to install in your trawler’s bilge. In the photo on page 11, you see a fiberglass sailboat batten (which doesn’t absorb water or decay while soaking in bilge water). I’ve marked the batten using different colors of electrical tape to identify varying “tide” levels. You could design a more accurate measure using numbers by the inch, but the specific precise level is not as important to me as determining if the level of bilge water is holding steady, going down or filling up. On the engine room checklist I provide to my clients, I have a check-off box to indicate the bilge water level. This simple type of visual measurement — being able to eyeball the “bilge tide” — gives me more confidence that I’m tracking the rise and fall before it gets out of control.

If you look closely and inspect your bilges with a flashlight, you can almost always find an unwanted piece of scrap that has found its way into your bilge. These wandering pieces of plastic, wood shavings and other debris can hide deep in the bilge and only become known when they block your intake. One trick I favor is to carry a wire coat hanger on board that I can bend into a hook and extend to fish soft “fabric” items out of the bilge like rags, towels, etc. You can also purchase a long-reach grab tool (designed for picking cans off of high shelves) to clamp on and pick out solid items from your bilge.

Bilge maintenance

Keep your bilges clean and it’s easier to manage what is going on. When you are tied up to the dock, safe and secure, it is an easy time to flush out your bilge with fresh water, presuming that you are in a discharge area and that you aren’t sending pollutants overboard.

Diesel and oil can deteriorate the soft rubber diaphragms that do the pumping, so if you do end up running fuel or oil through your bilge pumps, remember to flush out each pump individually by running multiple freshwater cycles after you have appropriately disposed of the oily muck.

To give your bilge a bath, turn off any automatic bilge pump breakers and fill your bilge with environmentally safe sudsy soap that smells fresh. Let it soak for a bit and use a long scrub brush to scour the sides (or a Scotch-Brite pad on a stick). Turn your breaker(s) back on and discharge the soapy water. You might end up with some frothy air bubbles; if you do, dilute your bilge with more fresh water, rinse and repeat. A freshwater bilge pump out is good exercise for your bilge pumps as it also cleans out the working parts inside and clears the hose runs.

When you have achieved a clean, dry bilge, lay in a bilge boom to absorb petroleum byproducts. This would also be a good time to re-line the oil pans under your engines with fresh absorbent pads.

Jeff Merrill, CPYB, is the president of Jeff Merrill Yacht Sales, Inc. (www.JMYS.com). He is a veteran yacht broker who provides individual attention and worldwide professional representation to buyers and sellers of premium brand, oceangoing trawlers. Merrill is active in the cruising community as a public speaker and writer and enjoys spending time at sea with clients. Jeff has written several “Dialing-In” your trawler articles for Ocean Navigator’s Power Voyaging column and is constantly looking for new ideas to improve and simplify the trawler lifestyle. If you have a suggestion or want to get in touch, please e-mail Merrill at: Jeff.Merrill@JMYS.com.