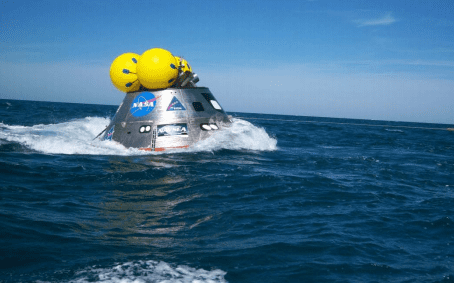

Voyaging boats carry sea anchors to deploy in storm conditions. Who knew that spacecraft also needed sea anchors? For NASA's upcoming Orion capsule, a sea anchor will be used following the spacecraft's splashdown to slow the 18,000-lbs. capsule's rate of drift and orient the capsule properly while the crew are picked up. Fiorentino Para-Anchor has been awarded the contract to provide sea anchors for Orion and recently the company conducted tests in the harbor at Long Beach, Calif., on the sea anchor that will be used for the Orion capsule.

From the press release: Representatives of Houston-based United Space Alliance, subcontractor to Lockheed Martin on the Orion project, watched the test in the harbor at Long Beach, CA.

Zack Smith of Fiorentino’s Research and Development Team conducted the test involving load strengths and drag characteristics of a six-foot diameter parachute sea anchor, including accessory components of rope, bow shackle and snap shackle, towed by a crewed 100-foot tug vessel. The test was conducted principally to measure drag characteristics, including force and other critical elements, in evaluating the equipment for its ability to stabilize a space module upon sea impact.

At the end of Orion’s planned 2014 unmanned Exploration Flight Test 1 (EFT-1) mission, the 16.5-foot diameter, 18,000 lbs. crew module capsule is expected to splashdown in seas up to Sea State 3 (the general condition of the free surface on a large body of water with respect to wind waves and swell at a certain location and moment, in this case 0.5 to 1.25 meters wave height with sea characteristics as ‘slight.’).

Wulf von Eckroth, design engineer with United Space Alliance, noted that two Fiorentino chutes (one for actual use and one for back-up) will be used to stabilize the floating spacecraft crew module. “We wanted the test to load the six- foot diameter Fiorentino Para-Anchor to about 330 pounds which is equal to 150% of the expected load that the capsule would encounter in Sea State 3 conditions, “ he says . “ We got to 330 pounds for the functional load test and we took it even beyond to 800 pounds for five minutes, proving the Fiorentino parachute anchor performed above the 150% requisite load test we required so the test was successful. “

Gary Rohrkaste, United Space Alliance project manager for the Sea Anchor explained, “Orion will always have a water landing and the Para-Anchor drag chute will be used on all capsule recoveries. The capsule has very little draft and wants to move right along the water. The parachute keeps the capsule from drifting too fast in the water and orients the large module for the rest of the recovery.”

The Orion spacecraft is America’s next human space flight system being developed with capabilities to take astronauts on long-duration, deep space missions beyond low Earth orbit to future destinations like asteroids, the moon and someday Mars. During the 2014 unmanned flight test, Orion will reach an altitude of 3,600 miles over the Earth’s surface, more than 15 times farther away than the International Space Station, and then return for a splashdown. NASA’s currently plans a second unmanned Orion mission in 2017 and a manned mission in 2021.

“Parachute anchor test #13, (the chute has gone through 12 prior tests on other projects) is primarily useful to the Orion project in determining the strength of the individual parts making up the drag device, “says Zack Smith. “It also provides information on how much or how little the product spins or yaws or if a specific part fails to perform correctly.”

For the tug test, according to Smith, a tension load cell was utilized that measures the amount of force placed on the object to which it’s attached and a battery operated digital indicator that registers the numbers on a monitor. For the test, the load cell was attached to an amidships rope bridle (with virtually no stretch), anchored to port and starboard posts. A 96.6-foot, 5/8 inch double braid Dacron/nylon rode (which does stretch) with splice and thimble on both ends of the rode was attached to the “eye” of the load cell that faced the tug’s transom. The measurement from the load cell “eye” to the boat’s stern was 25 feet.

Smith reports that an inspection of the parachute sea anchor and all the stainless steel hardware used in the test showed no sign of damage or wear throughout the entire system. Charts of drag speed characteristics and recorded measurements in Tech Report FPA-152 are available on Fiorentino’s website at www.para-anchor.com/info.perform.html.