Designing and building a truly capable offshore cruising sailboat requires more than cutting-edge naval architecture, state-of-the-art construction techniques, and complicated systems engineering. These are, of course, critical components of any successful yacht design and construction, but as “successful” or “popular” as they may be, without vision and hands-on experience as primary input to the process, many designs simply become ongoing experiments in product development. That approach to design is typically driven by popular trends, market forces and façade rather than functionality, safety, performance, reliability, and comfort.

Thankfully there are designers and builders whose lives have been defined by their experiences, love of boats, and the sea. A longstanding collaboration between designers Chuck Paine, Ed Joy and Lyman-Morse Boatbuilding Co. have brought this sort of real-world experience together. The result is a boat designed and built to go to sea, the result is the Lyman-Morse 55.

|

|

Courtesy Lyman-Morse |

The designers, Paine and Joy have long been recognized for their successful offshore cruising designs. Together with an experienced builder and the bluewater experience of the yard’s owners Cabot and Heidi Lyman, the LM 55 may very well be the ultimate world cruising yacht.

The Lyman’s have gained experience circumnavigating and a lifetime of cruising with their children as well as through building more than 100 offshore boats. Their experience with what works and what does not work has been captured in the development of the LM 55.

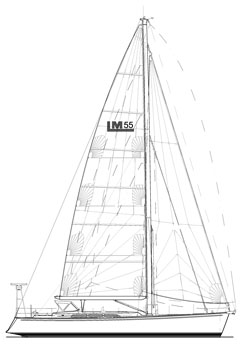

The LM 55 is a moderate displacement hull with a high ballast ratio capable of handling a large rig. There is a fine bow entry with a modest overhang forward which enhances the overall profile. The freeboard is moderate with a substantial mid-ship section for maximum stability. The boat has a handsome sheer and the stern is designed to minimize squatting and help provide maximum speed in a following breeze.

|

|

Interior of the LM 55 looking aft toward the companionway showing the open plan. |

|

|

Looking forward showing the galley and pilot berth at left. |

The hull is constructed of rugged resin infused E-glass and vinylester rather than more exotic composites in order to reduce building costs and simplify repair work in remote locations. As a boatbuilder, Lyman understands the need to make repairs as practical as possible and to that end he has also built all of the spars out of aluminum which is strong, easily repaired and cost effective when compared to carbon fiber. All of the rigging components have been selected with worldwide availability in mind.

In terms of performance, the boat is stiff and sea kindly. The deck is laid out for shorthanded sailing with most halyards and reefing lines led to the cockpit. The mainsheet track is forward of the cockpit and led to a dedicated winch.

For simple and safe sail-handling there is a slab reefing system with lazy jacks. The 110 percent jib and staysail flies on manual roller furling gear and the Code Zero and asymmetric spinnaker are attached to the end of the anchor roller hardware.

The cockpit is arranged so that the crew can operate from under the protection of the dodger. Primary and secondary winches are mounted atop the coaming and there are inboard and outboard genoa tracks to maximize sail trim. The deck is clean with a flush foredeck and a large sail locker hatch for easy access.

For safety, in addition to lifelines, there are waist-high stainless steel rails on either side of the mast, at the bow, and surrounding the cockpit. Deck hardware is custom cast and oversized for docking and carrying a drogue.

Navigation/communication antennas are mounted on a stainless steel stern arch, keeping them out of the way but also providing for accessibility for repairs. The arch also has a pivoting davit for bringing aboard an outboard and is fitted with two 240-watt solar panels, providing power to run the refrigeration system and keep the batteries charged. There is no genset for the sake of simplicity.

There is a single helm. When the autopilot is engaged the wheel can be disconnected from its shaft, reducing energy consumption. In port the wheel can be removed from the helm and stowed in the large stern lazarette. The cockpit coaming is open to the transom, which has a sugar scoop platform for easy access to the tender, swimming, and emergency reboarding.

|

|

Planned deck gear setup on LM 55. |

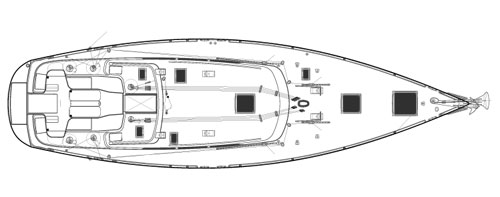

Below deck, the boat is practical, comfortable, but far from Spartan. The interior styling has beautifully finished joinery and a wood striped overhead. The interior layout is open but secure in a seaway with special attention paid to open space dimensions and proximity to grab rails. Six dorade vents provide great ventilation throughout the boat.

There is a forward cabin with a centerline double berth and en suite head and stall shower. Moving aft into the main saloon, a U-shaped settee and dining table occupy the port side, and another settee/sea berth is to starboard. The galley is located immediately aft of the dining area. Counter space is ample with top-loading reefer/freezer units and twin 10-inch deep stainless steel sinks. The boat carries 310 gallons of water eliminating the need for a watermaker.

Opposite the galley to starboard there is a secure aft facing nav station for easy communication with the cockpit. Aft accommodations include two guest cabins, which share the day head. A wet locker for foul weather gear is immediately aft of the head.

The starboard cabin has over and under single bunk and the port cabin has a V-berth that is expandable to a double with an insert.

For auxiliary power the boat is equipped with a high torque Perkins M92B diesel capable of pushing a fully loaded boat at eight knots in a stiff headwind.

Lyman-Morse intends to build the LM 55 as a robust, basic boat and give the owner the flexibility to specify equipment and electronics to suit their particular cruising needs.