What do Great Barrier Island in New Zealand and Toau Island in the Tuamotus of French Polynesia have in common? The former is tall, lush, green and temperate; the latter flat, palm-studded and tropical. And they are both where we were on our J/40 Gryphon when the diesel lift pump died, leaving us powerless.

“Not such an inconvenience for a sailboat,” you might think, but neither island is particularly friendly when it comes to entering or leaving their protected inner waters. So it was in both cases that we had to find a solution to this common problem.

The lift pump on our elderly Volvo 2003T is a familiar design, little changed over decades: A mechanical lever actuated by a cam inside the engine alternately lifts then releases a rubber diaphragm, which is returned by spring action. The moving diaphragm creates a suction that lifts the diesel from a supply tank lower than the engine through a set of check valves to the engine. Common failures are mechanical failure of the check valves and deterioration of the diaphragm, which, once perforated, fails to do any useful work.

|

|

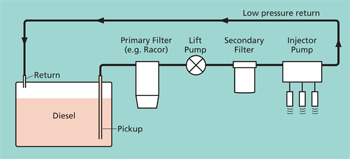

A schematic of diesel fuel flow. |

In the Tuamotus, we were already safely secured inside the lagoon when the pump failed, but the paucity of supplies made repairs a real challenge — I couldn’t figure out how to fix it with a coconut. The weekly copra freighter gave us a sheet of gasket material, but the prefabricated design of the pump’s diaphragm wouldn’t allow a simple replacement of the rubber material.

The solution finally came from a friendly yacht calling at the same anchorage — this boat happened to have a spare electric fuel pump on board. Refusing anything more than a six-pack of beer in exchange, they graciously gave us the spare.

Plumbing the new pump in would require cutting the existing mechanical pump’s hose, so any change was going to be difficult to back out of. But the new pump seemed about the same size and the fittings were almost the same diameter as the hose, so, hey, what could go wrong?

|

|

The replacement electric fuel pump. |

|

Jeff Williams |

Lift pumps serve a simple function; they keep an adequate supply of diesel fuel available to the injection pump that’s feeding the injectors. Any excess supply from the lift pump simply cycles back into the diesel tank through the return line.

Happily, the fuel fitting on the engine is the same as on the lift pump, so the temporary repair only involved removing both in and out lines from the lift pump, cutting the line that ran between the Racor primary filter and the lift pump and inserting the new pump there, and attaching this modified line directly to the input of the engine.

The new pump was 12 volts so no rewiring of batteries was needed. I just connected the pump to the “run” side of the engine electrics; the pump runs whenever the key is on.

A couple minutes to bleed the injectors and our engine, nicknamed “Stinky,” was back in proper form.

Replacement fuel pumps are not that easy to find, however — Tahiti, Rarotonga and Tonga all came up dry. Instead, a visiting friend delivered one to Tonga. I installed the new pump and a bronze hose-barb fitting to repair the cut hose and we were as good as new … until recently anyway, just outside Great Barrier’s Port Fitzroy entrance known ominously as The Narrows.

This time the repair took less than an hour. We had kept the electric pump as a backup, complete with wires and labeled connectors. The old useless lift pump stayed on the engine and just the hoses had to be rerouted again. Running the electric pump for 30 seconds had the secondary engine-mounted filter primed and then it was a routine matter to bleed the injectors and have the engine running again.

|

|

Fuel lines, the bottom line is the original line and the longer top is the flexible replacement hose. |

|

Jeff Williams |

It was surprising that we only got about 500 hours of service from the failed mechanical pump. I disassembled it and found that a piece of the casting had broken and the one-way check valve was no longer preventing backflow toward the tank.

Our next mild surprise was that this model of lift pump had been superseded. Unfortunately, a corollary of Murphy’s Law insists that the “new and improved” lift pump have the inlet and outlet ports in different places than the original. This meant that the factory fuel pipe between the lift pump and the engine-mounted secondary filter had to be replaced in favor of flexible hose with the same fittings.

We had a diesel shop set up a short piece of fuel line with one banjo fitting. On board, we custom cut the hose and fitted the other banjo fitting with a permanent clamp.

With the new mechanical pump installed, our Tuamotu treasure was again safely stowed — for next time.

Contributing editors Jeff and Raine Williams are still sailing their J/40 Gryphon in their adopted country of New Zealand.