You’ve been watching the storm front creeping ever closer and you have 45 nm to go. You wonder if there is enough fuel to go the distance. There are two things you need to know before you can be sure: How accurate is your gauge and tank sender?

You’ve got your power voyaging boat set at its best cruise speed and are getting 0.7 nm to a gallon. You want to speed up to beat the approaching front. The bouncing fuel gauge appears to say there is slightly more than a quarter tank, and you do the calculations. At full speed you get 0.5 nm to a gallon. Your tank capacity is 400 gallons so you should have about 100 gallons of fuel. You’ll need 90 gallons. Do you actually have that much fuel?

The gauge

To understand how all of it works, we have to know the magic numbers of 33 ohms (your tank is full) to 240 ohms (your tank is empty). This resistance range is read by analog marine fuel gauges, and the gauge needle theoretically points to the corresponding fuel level. For example, if the circuit resistance is 103 ohms the needle points to half full. More sophisticated sender technologies emulate the 33 to 240 ohm output for standard fuel gauge use.

Fuel gauges come in two forms. The typical analog versions, and the digital forms. We’re not going to dwell on the analog fuel gauges with the pointing needle since most are familiar with them. They work reliably, but only provide generalized information on how much fuel you actually have.

Digital fuel gauges can do much more with the same 33- to 240-ohm input. Instead of pushing a needle around a dial, a 100-gallon tank with a 103-ohm reading now says you have 50 gallons. Since we now know how many gallons we have, gauges like the CruzPro FU60 can manipulate the information and calculate current consumption rate, time to empty, and fuel used on a trip. The CruzPro gauge also has tools that allow calibration of irregular tank shapes, and the ability to transmit the data with a NMEA 0183 output.

Your chartplotter in many cases can also be a fuel gauge by using a NMEA 2000 converter like Maretron’s TLA100 attached to the sender. The data will appear on most systems as a digital simulation of an analog gauge. Since this unit allows calibration, it’s capable of dealing with irregular tank shapes.

The tank

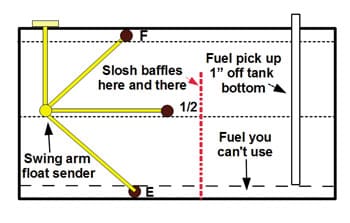

Before we deal with the abundance of available fuel sender technologies, we have to take a few minutes to consider the tank it’s attached to. The first item we can’t use is all of the fuel we have in the tank, and we don’t want to. The fuel pick up is usually mounted about an inch above the tank bottom. The bottom of the tank is where water from condensation has settled, along with any solids in the fuel. But this fuel needs to be accounted for, and it’s easy to do.

Measure the tank’s width and length in inches, and multiply them together. Then divide this number by 231 (number of cubic inches in a gallon) to get the not usable gallons. If you’re going to install a new sender, you might as well get the math finished. In inches, length by width by height gives you the total cubic inches in the tank. Divide this number again by 231, and you now have total gallon capacity.

The typical sender is attached to the top of the tank using a Society of Automotive Engineers (SAE) specified five-hole bolt pattern. Despite the appearance of symmetry, the hole pattern only allows the sender to mount in one orientation. There is also a variation used by some tank manufacturers that has a four-hole pattern, so check first and don’t be caught by surprise.

Senders

There are a huge array of technologies available to measure fuel tank levels from old school approaches such as the measuring stick or sight glasses, to sophisticated ultrasonic and capacitance based systems.

|

|

Courtesy Hardin Marine |

|

Capacitance senders like this Hardin Marine unit provide high accuracy at low cost. |

Resistance senders

The resistance based float sender is by far the most commonly used and least expensive. The float on the arm rides at the current fuel level, and the ohm reading is dependent on the angle of the elbow. It is a well-tested device, but over time floats may deteriorate, or come off leaving you with an empty tank reading all of the time. Problems can also occur if there is wear causing the wiper to encounter locations with no conductivity, and sloshing fuel in rough waters will cause bouncy gauge readings.

Another variation of a resistance style sender is Moeller’s reed switch based sender. A magnetized float slides on a tube actuating reed switches that create a specific ohm reading.

Capacitance senders

This type of sensor measures the capacitance between two probes. As the fuel rises, the capacitance between the tubes increases, and vice versa. In the case of the Hardin Marine sensor, the sensing is done inside the tube, which makes it nearly immune from fuel level changes caused by sloshing fuel. The electronics potted inside the sender read the capacitance values, and converts them to readings of 33 to 240 ohms used by standard marine fuel gauges. This style of sensor is about 99 percent accurate.

Ultrasonic senders

This technology, like the capacitance based sender, offers very precise level sensing. Fuel sloshing around inside the tank is digitally smoothed to produce a solid level reading. Units like BEP Marine’s TS1 are a good option for larger tanks. Most of these require some amount of advanced programming done by the manufacturer. In BEP’s case most users accomplish this by filling in a worksheet with the tank dimensions when they order. For more complex tank shapes, an optional programming interface kit is available. This technology is also ideal for scenarios where access above the sender is not possible without heroics since it does not protrude notably inside the tank.

Pressure sense senders

The last option is one that is more commonly used in industrial applications, but still works well for power voyager’s fuel tanks. An example of this unit is Maretron’s FPM100. The pressure transducer is mounted through the wall of the tank at the bottom, and it is suitable for many fluids, including diesel. The data is transferred via a NMEA 2000 network.

No matter what sender you’re using or its precision, if it’s attached to a standard analog fuel gauge, you will never have more than a general sense of how much fuel you actually have, and no sense of how fast you’re using it. To make things a bit worse, not all senders sold for marine use are exactly 33 to 240 ohms, and corroded sender connections can increase the resistance making it appear as if you have less fuel. Some standard fuel gauges are also more susceptible to voltage changes than others, creating reading errors.

A good capacitance or ultrasonic sender when combined with a device like the CruzPro digital gauge are your best options to getting reasonably accurate information you can really use from your fuel tank system. Fuel monitoring systems like Floscan weren’t discussed here because they can’t provide real-time tank level information, but these systems are also part of the bigger picture for the serious power voyager.

———–

Bill Bishop is a marine electronics installer based in Sarasota, Fla. He also writes an entertaining blog about his installation experiences called The Marine Installer’s Rant: themarineinstallersrant.blogpot.com.