Once I settled on a Tayana 37 pilothouse boat as my choice to allow me to tick off the primary item on my bucket list (circumnavigation), I set out to find a suitable used boat.

At the time, I was not able to find any boats on the market that did not have teak decks, and by the time I factored in the cost of removing a teak deck from a used boat, I was right up against the cost of a new boat. So, for the first time in my life, I bought a brand-new boat.

This brought with it emotional issues that I had not planned on. All my previous boats had come to me with a few scars that reflected on the modifications of the previous owner(s), as well as those of a few docking indiscretions. So, I did not feel like I would be doing much damage when I drilled the holes I needed to install new gear.

But my Tayana 37, Active Transport, was delivered in pristine condition, and I had a real problem picking up my drill and making holes.

That’s when I started trying to find ways to install things belowdecks that did not require drilling holes. I’ll discuss a few examples to illustrate the major categories of solutions I have come up with and leave it to you to figure out the details for your boat. I have also used one of these solutions above deck, though never for mission-critical gear. Everything that takes any kind of load is always through-bolted.

Drilling holes in teak was traumatic enough, but at least those holes are easy to repair with teak plugs. The real problem, for me, was drilling into the white plastic parts of the ceiling and overhead, where a cosmetically invisible repair was much harder to pull off. Besides the benefit of avoiding the trauma associated with drilling holes in my boat, I think I have also done a lot to preserve value for when the day comes to sell it.

Hole-free attachment alternatives also give me the freedom to try positioning things where I want them without overthinking it. If I change my mind, it’s not a big deal if I have not drilled any holes.

There have been situations where hole-free options would not be adequate. The 32-inch TV is securely attached to a bulkhead, for example. But my rough estimate is that I have avoided drilling at least 100 holes in the cabin of my boat during the 17 years I’ve owned it.

Port blinds

I needed some way to prevent sunlight from shining directly on the varnished surfaces and to provide privacy when at a dock, but drilling holes to mount curtain rods and having custom curtains made did not really do it for me.

|

|

The CloZures vertical blinds John Lewis installed on his boat, shown closed in the top image and open on the bottom. |

I discovered a new product (new in 2003, that is) that was called “peek-a-boo shutters,” made by Zarcor. The name seemed dumb, and the company eventually changed the name to CloZures.

CloZures are attached to the glass of the ports using round dots of 3M Dual Lock tape (more about this miracle material later). The CloZures consist of two pieces of thin polycarbonate, one of which is attached to the glass while the other slides back and forth to open or close the shutters. Vertical bands of paint are silk-screened onto the polycarbonate. When the bands line up on top of each other, you can see out; when the inner piece of polycarbonate is slid so the bands are side by side, you cannot see through them.

At first, looking through the shutters seems like looking out through the bars of a jail cell, and the photos make this look worse than it really is. Your brain quickly learns to ignore the vertical bands when you are looking out through the ports.

My CloZures have been in place for about 17 years and show no signs of needing to be retired. I have replaced the tiny nylon rivets that hold them together due to sun damage, and I occasionally take them off the ports so I can clean the glass, but otherwise they have been maintenance-free. Most of them are still attached with the original 3M Dual Lock dots. Zarcor sells all the replacement parts.

In addition to the privacy aspect, these shutters also protect the varnish in the cabin from UV light. The Tayana boats have an epoxy-based varnish on interior surfaces, and while it’s great for protection from beer cans and other abuse, epoxy does not stand up well to UV exposure. In a few places where UV does shine on the interior woodwork, there is sun damage — but there is no damage in the areas where the shutters have been protecting the wood finish.

Zarcor also sells similar shutters for overhead hatches, and in retrospect I wish I had installed a couple of those, too. The worst sun damage to the varnish is in places where sunlight comes in through the overhead hatches.

There are some good illustrations on the Zarcor website that illustrate how these CloZures shutters work (www.zarcor.com/products/clozures/index.php).

A paper towel holder

I could not figure out a place to mount a paper towel holder that involved drilling a couple small holes in the galley teak rather than in the plastic on the inside of the coach roof. The logical place for the holder was against a white plastic surface, and I have already discussed my concerns with drilling holes in those surfaces.

So, I took a chance on an idea I came up with: attaching a teak batten to the plastic using silicone sealant — a method from before I knew about the 3M Dual Lock.

|

|

3M Dual Lock tape connects with itself — no need to worry about hooks and loops. |

I put a couple of T-nuts into the backside of the batten so I would not have to worry about the tips of the self-tapping screws damaging the plastic surface of the coach roof when I attached the paper towel holder. Now, I have been able to attach several paper towel holders over the years by inserting machine screws into the T-nuts.

The teak batten has been in place for 17 years and shows no sign of coming off. I took a chance with this because I figured getting hit in the head with paper towels was not a major worry should my solution fail. Besides, I have been hit in the head by worse things.

3M Dual Lock

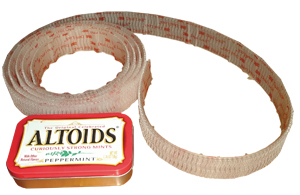

The closest I ever come to sounding like an evangelist is when I’m telling friends about the properties of 3M Dual Lock. Dual Lock is sort of like Velcro, but rather than being a hook-and-loop arrangement, it is a system with hooks on both sides of the fastener. The hooks are made from polyethylene and the connection that results is very strong. You don’t have to worry about having equal amounts of hook tape and loop tape on hand; Dual Lock fastens to itself.

There are things mounted on my boat using Dual Lock that have been in place for 17 years. There has only been one failure that I’ll mention below.

Dual Lock is very good for applications where you do not anticipate making and breaking the connection on a regular basis. For one thing, it holds so well that it can be hard to get it apart, but also the hooks seems to loose their tenacity when you make and break the connection frequently. It’s not a problem if you must occasionally break the connection for things like replacing batteries in devices secured with Dual Lock. I’m sure the attachment would hold up for at least 100 make-and-break cycles.

|

|

Two power strips in the galley held in place with Dual Lock. |

Even though the hooks connect very securely, it is not difficult to remove the Dual Lock tape, even years later. I have removed Dual Lock that had been in place for up to 10 years and saw no damage to the underlying surface. You simply peel up one corner with your fingernails and grab it with pliers to pull it off the surface slowly. The only reason you have to pull slowly is so the Dual Lock material does not break and force you to start over.

Here are a few examples of applications I have found for Dual Lock:

• The navigation computer (Acer Netbook) that took us around the world was secured in the nav desk with four postage stamp-size pieces of Dual Lock. It has never shown any signs of moving. USB hubs and other computer accessories are similarly fastened with Dual Lock.

• All of the pictures and paintings in the cabin are secured with Dual Lock strips. Usually a couple pieces the size of a postage stamp is all it takes. None of the framed pictures or paintings have ever come loose during the 50,000 sea miles that were logged when I was out cruising.

• Terminal strips for 110-volt AC can be stuck in place with Dual Lock and won’t come loose unless you want them to.

• I have secured motion-activated lights under the cockpit cover and under the radar arch (over the gas grill) with Dual Lock. Both have been in place for years and show no signs of coming loose. In the applications involving devices with batteries, it’s a good idea to avoid covering the battery access panel with Dual Lock. Don’t be hesitant to cut weird shapes — it works just as effectively.

• The 21-inch TV in the forward sleeping cabin is mounted on a teak board that is attached to the cabin side with strips of Dual Lock.

The only time Dual Lock has failed me was when I used it to attach an Android box for the TV to the overhead, and the heat output of the box softened the Dual Lock adhesive. However, I never had any problem with Dual Lock in hot tropical climates.

|

|

An array of cooking utensils set on Command hooks — no holes were drilled to put these up. These items all come down for stowing in a bunk when Lewis heads to sea. |

You can find Dual Lock at some chandleries, but many won’t sell short lengths. You can, however, buy short lengths on Amazon. You don’t need that much; six feet will last a long time.

3M Command hooks

Once again, 3M comes to the rescue. I suppose it’s not surprising that the company that developed the adhesives that hold modern car bodies together would also have a lot to offer boaters.

Command hooks are available in most hardware stores and on Amazon. They are designed for household applications as varied as hooks for hanging clothes, cable organization (I use the ones they designed for Christmas lights for that purpose) and attaching various fixtures for the galley and head.

There are several mounts for things like cellphones and tablets that use 3M Command adhesive strips.

I used several Command hooks around the windows in the pilothouse on Active Transport to allow me to secure a car windshield-type sunscreen in place when bright sunlight made it difficult to see the nav computer screen.

The adhesive strips that are used to attach Command hooks have not damaged any surfaces. They hold tenaciously and, in my experience, are good to hold a lot more weight than the manufacturer specifies. Extra adhesive strips are available in case you don’t like your original location.

|

|

The port side of Lewis’ nav station has a Bluetooth speaker resting on a window frame with Dual Lock holding it to the glass. A USB hub and document scanner are mounted with Dual Lock. |

Magnetic cellphone mounts

I was skeptical about magnetic cellphone mounts at first but eventually decided to give them a try. Now, I use them for lots of applications.

First and foremost, they are very good at attaching a smartphone to a surface in the nav station, in the galley for keeping recipes handy, by a bunk or in the car. You don’t have to fuss with lining the phone up perfectly or closing a mechanical clamp to hold the phone — just put the phone on the magnetic mount and it’s secure.

I have not crossed oceans using these mounts, but I have been out in bouncy conditions in Southern California and down the coast from Washington and never had reason to worry about my phone coming adrift.

These mounts come with some thin steel plates that stick to the back of your phone or inside the phone’s case. The only magnets are in the mount itself.

I have always used the 3M adhesive pads that come with the mounts, but in retrospect I wish I had removed that stuff and replaced it with Dual Lock just so it would be easier to remove when the time comes.

In addition to my phone, I have used these mounts to secure remote controls and the wireless thermostat that I use to control the space heater on the boat. You can get these mounts on Amazon, and you can cut the steel plates with scissors to make them fit on other objects like TV remotes.

The type of magnetic mount I have been using would interfere with wireless charging of cell phones. There are some new designs on the market that are designed to be compatible with wireless charging, but I have no experience with them.

|

|

A magnetic phone mount and charging cord held in place with a screw and loop. |

Use screws already on boat

Some of the cabin trim in Active Transport is held in place with stainless-steel screws and finishing washers. The builder used that solution — instead of screws covered with wood plugs — in places where it was anticipated that occasional disassembly might be necessary. The front panel of the cabinet where the microwave is mounted is held in place by visible screws. The screws can also be used to capture wire clamps to organize cables without the need to drill a hole. The same is true for the wood battens between the plastic panels on the overhead.

Before I did the 1994 single-handed Transpac Race, the Singlehanded Sailing Society organized seminars for the participants. One was presented by a well-known San Francisco Bay Area sailor named Mark Rudiger, whose subject was emergency repairs at sea.

The one thing I will always remember from his very entertaining presentation was that the first thing you should do when something goes wrong at sea is nothing. He advocated stepping back and assessing the situation. That advice has always served me well, and I would like to extend Mark’s idea to include situations in which you find yourself reaching for your drill to install a new piece of gear. Give it a few minutes and ask yourself if there is some way to accomplish the same goal without drilling holes.

John Lewis circumnavigated aboard his Tayana 37, Active Transport, sailing more than 50,000 miles.