Not many power voyaging vessels put 100,000 sea miles under their keels — a figure that includes multiple Pacific crossings. For the Northern Marine 75 Starr, owned by Don and Sharry Stabbert, that kind of mileage has become routine as the Stabberts have voyaged to more than 18 countries around the world. Starr was designed by Steve Seaton and built in Anacortes Washington in 1997. The 100-ton power voyager is currently homeported in Hawaii and Seattle.

The Stabberts have owned a variety of boats, from a 17-foot Thistle sailing dinghy to a Cal 40 sailboat to 47-foot Bill Garden-designed trawler. Based in the Pacific Northwest, the couple cruised extensively in southeast Alaska before acquiring Starr in 2000. In recognition of the Stabberts’ extensive voyaging on Starr, Don and Sharry were awarded the Cruising Club of America’s Far Horizons Award in 2021. The Stabberts are owners of the Salmon Bay Marine Center (SBMC.com) boatyard in Seattle.

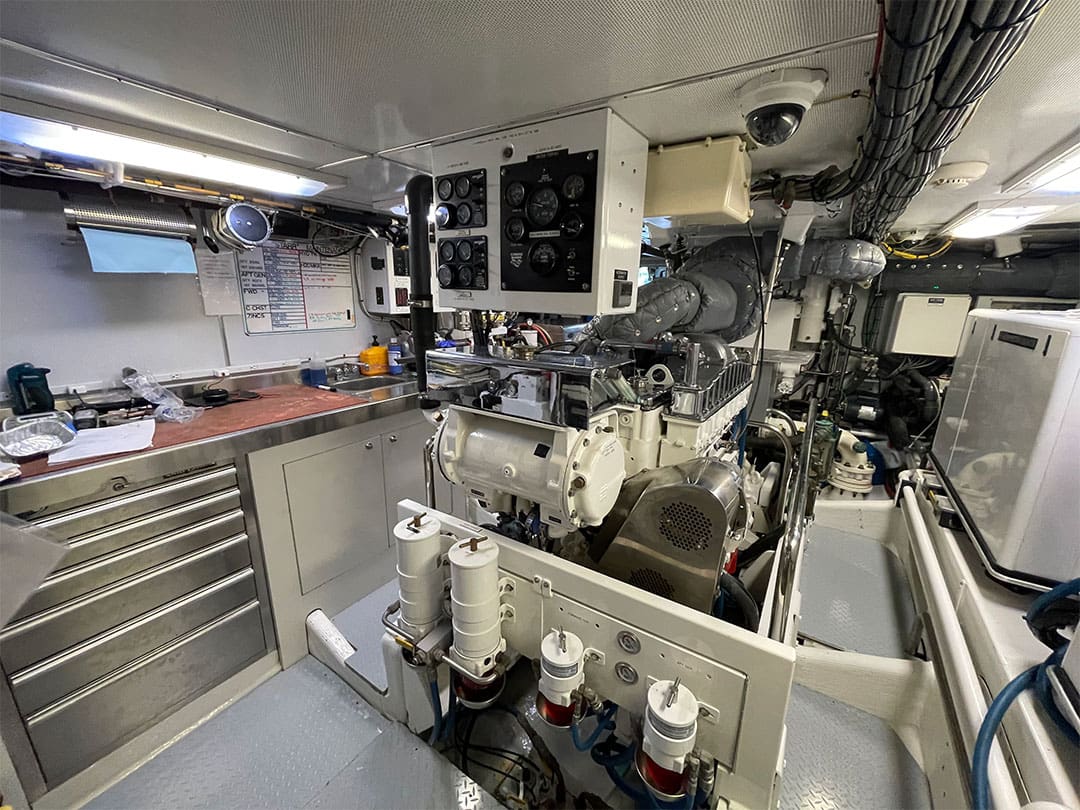

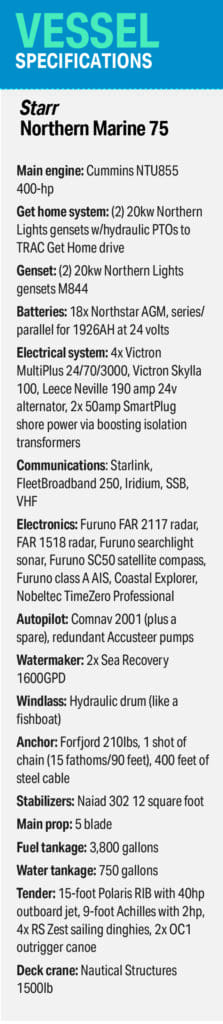

Unlike many larger power voyaging boats with twin engines, Starr is powered by a single Cummins NTU855 400-hp diesel driving a 50-inch, five-bladed prop. The power voyager has has a cruising range of approximately 4,000 nautical miles. When running at eight to nine knots Starr consumes approximately one gallon per mile. By throttling back to six knots, the boat’s range can almost double to more than 7,000 nautical miles. Rather than having a separate “get home” diesel engine with its own shaft and prop, Starr has a backup propulsion system that powers the prop shaft using two 20kw Northern lights gensets that have hydraulic power take offs that provide power to a hydraulically-driven TRAC Get Home Drive that turns the main shaft. This genset/TRAC setup will push Starr at 3.5 to 5 knots. Don wrote in the Stabberts’ blog: “Over the past 20 years and more than 100,000 nm of running and 13,300 hours on the main engine, we have only used our get home once which was on a passage between the Marshall Islands and Micronesia in 2010.”

Starr has a customized rudder setup that aids in handling the 75-footer. Very early in their ownership of Starr the Stabberts realized that the vessel’s steering characteristics needed improvement. Don wrote in an email: “When we bought the boat, we weren’t satisfied with the steering response. The boat would wander and required a fair amount of counter rudder before it would go straight after making a turn. As a skipper of single screw tugs, I knew this wasn’t how it should handle.”

The solution was to add twin rudders. “This gave us 24 square feet of rudder area vs the original 12 square feet,” Don wrote. “The rudders, spaced 37-inches apart on a 50-inch, 5-bladed prop, are angled one inch into each other giving a slight nozzle effect.” In order to mount the two rudders, it required extending the keel shoe by adding a manta-ray type plate called a beaver tail. This plate also gives some added lift to the stern while Starr is underway. “Even in big quartering seas, the rudders rarely move more than a few degrees. It’s the single best upgrade we’ve done to Starr. The autopilot has such an easy job that we’re still on the original pump after 15,000 hours. We’ve been in 10-foot quartering seas at a five second period — almost breaking — and never saw the rudders move more than three or four degrees.”

For en-route stabilization Starr has 12-square-foot Naiad fin hydraulic stabilizers. “Underway they’re remarkably effective,” Don wrote, “and they’re more effective the faster we go. Naiad says they take out 90% of the roll, and we won’t argue with that claim! As long as the period of the waves is over about 10 seconds, our most comfortable course is with seas on the beam — not something you’d enjoy in most non-stabilized powerboats.” For stabilization at anchor the Stabberts use flopper stoppers.

For en-route stabilization Starr has 12-square-foot Naiad fin hydraulic stabilizers. “Underway they’re remarkably effective,” Don wrote, “and they’re more effective the faster we go. Naiad says they take out 90% of the roll, and we won’t argue with that claim! As long as the period of the waves is over about 10 seconds, our most comfortable course is with seas on the beam — not something you’d enjoy in most non-stabilized powerboats.” For stabilization at anchor the Stabberts use flopper stoppers.

For monitoring tank levels, bilge systems and battery state of charge, Starr uses a combination of systems. “The original system was custom built and monitors bilge high water, shore power, some engine parameters, and a few more things,” Don wrote. “Tanks use HeadHunter Tank Sentry monitors. For the last decade we’ve been adding Maretron monitoring equipment in addition to the original systems. We have many of the tanks monitored on Maretron, pretty much the whole AC and DC electrical systems, fire alarms, bilge counters, etc.”

On a vessel of this size, many owners would delegate boat work to others, but Don, who has ample hands-on experience, does most of the work himself. “I grew up as the ‘engineer’ on my family’s converted minesweeper,” Don related via email, “traveling the Pacific Coast, and I’ve always been a hands-on boat owner. I am constantly working to improve something on the boat. Some of my favorite projects are the dinghy cradle with lots of storage, the twin rudders, extending the swim step and lowering the cockpit rail, installing inflatable gaskets to make swim step hatches water tight…the list goes on and on. I’ve had my hands on every system on Starr at one time or another, but I’m not too proud to call on experts when I get stuck. We’re fortunate to have a wealth of marine industry expertise around our home at Salmon Bay Marine Center in Seattle, and I’m very thankful for all the experts who take my calls, listen to my problems, and put me on the right track to solving them!”

As for the Stabberts’ future voyaging plans, they are readying to depart on a North Pacific loop, from Hawaii to Japan, then to Alaska and Seattle, where Starr will have some work done, and then back to Hawaii. This will be their 13th, 14th and 15th Pacific crossing on the eminently capable voyager Starr. n