Marine refrigeration design, maintenance and repair

Over the past 25 years, first with a CSY 44 monohull and now a St. Francis 44 catamaran, I have spent countless hours and way too much money messing with my refrigeration systems. Early on, I needed professional help before attempting modifications, maintenance or repairs. Now, after all this time at it (for me, learning these things takes time) I am a bit smarter and can do most of the work myself. Below find some of what I have learned along the way about refrigeration equipment design, maintenance and repair.

Since big refrigeration systems are usually expensive and the largest energy consumers on most cruising boats, it is worthwhile having the most energy efficient and reliable system possible.

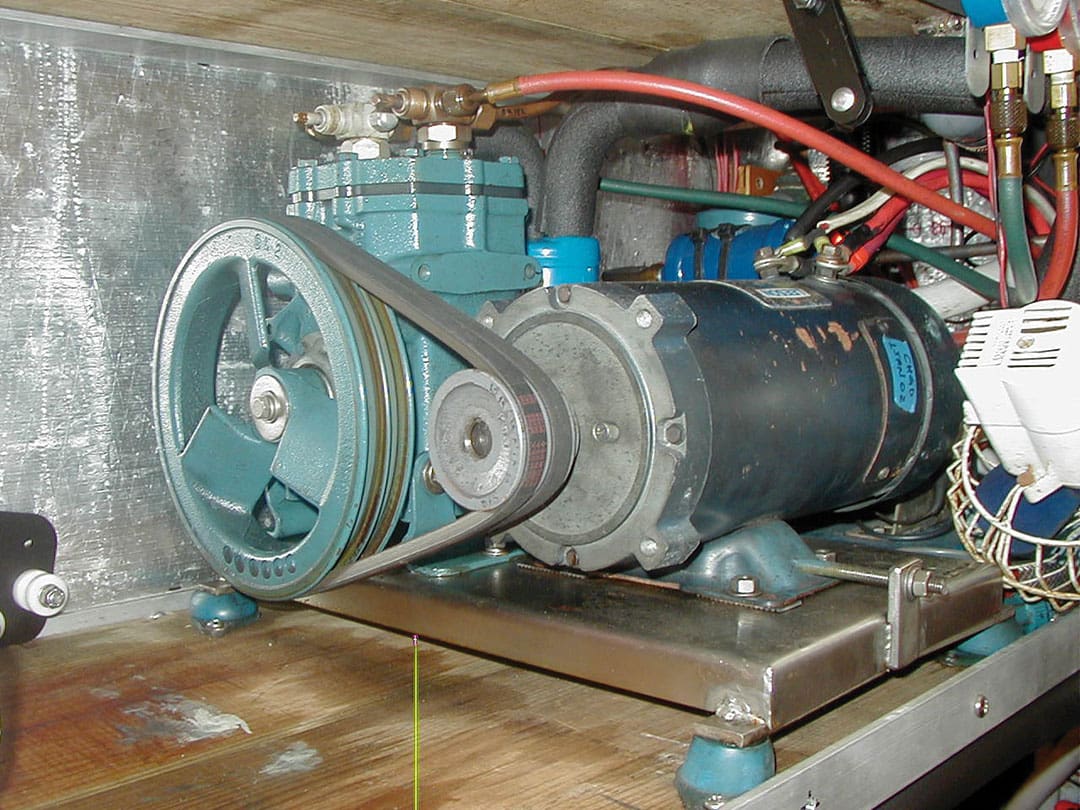

Older systems are based on a big heavy reciprocating compressor and multiple cold/holdover plates. These plates have a eutectic solution inside that freezes around the refrigerant tubing, allowing for several hours holdover before the system needs to turn on again. For large boxes this type of system requires running it for about two hours a day. I started in 1996 with a big engine-driven Crosby cold plate system, then modified it to work with a ¾ horsepower Leeson 12-volt motor, added a separate three-cubic-foot freezer box, and finally sold all of it in 2008.

Then we purchased two modern Frigoboat Keel Cooler systems. These modern marine systems are based on Secop/Danfoss compressors and thin aluminum or stainless steel evaporator plates. They are much easier to install, operate and maintain than the earlier cold plate systems. They are just as efficient, more reliable, allow a much tighter box temperature differential, are half the weight, almost silent running, and less expensive.

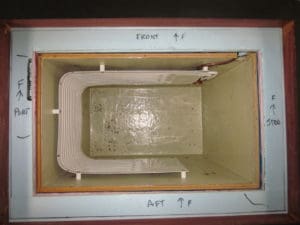

And since the compressor is constantly operating, just like a household refrigerator, the load is spread over 24 hours. This means that when running with only three to six amps current draw, instead of 30-40 amps with a cold plate system, there is far less effect on battery voltage. Four years ago I added similar systems to our catamaran and built a new eight-cubic-foot front-opening refrigerator box.

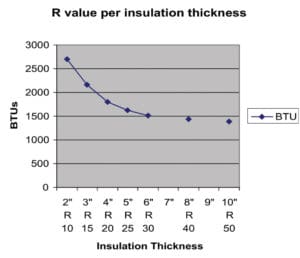

Cold boxes – The size, construction details, insulation type, and R value of your cold box, plus your cruising location ambient temperature, will determine daily heat load, and amp hour use. This will dictate which combination of compressor, evaporator plate and cooling system is best to use. It is worth doing a box calculation to see if your current or proposed system is right for your box.

For a refrigerator, a front-opening box is far more convenient and can be as energy efficient while cruising as a top-loading box,according to Glacier Bay, a well-known refrigeration maker, who did considerable comparison testing in the late 1990s. We have found this to be true ourselves, and really appreciate the ease of access to refrigerated items. This is not the case with a freezer, which should be top loading, due to the significantly increased differential between the inside and outside box temperatures.

Insulation and gasketing – Use of optimum refrigeration insulation is often overlooked during boat construction. Insulation R value is an indication of resistance to heat flow from the warmer outside of a box to the colder inside. The established goals are R20 for a refrigerator and R30 for a freezer. Less than that increases a compressor’s run time in order to remove the increased heat in a box. More than that does little to improve efficiency, but reduces the available box size.

According to Nigel Calder and Glacier Bay, the best commonly available insulation is extruded polystyrene (Dow blue or Owens Corning pink board in one- or two-inch thicknesses) which has an R value of up to 6.5 per inch at refrigeration temperatures. It is easy to work with and also does not absorb moisture. Properly installed vacuum panels have a better R value in a thinner size, but are fragile, more expensive and subject to puncture damage. Two part foam, often used in new boats, can absorb moisture and deteriorates over a relatively short time.

McCampbell’s front-opening refrigerator installed and finished.

The best door gasket material is solid ribbed EPDM rubber commonly available at most big hardware or refrigeration supply stores. Double gasketing is recommended for freezers to reduce heat gain in that area. Test the air tightness all around with a dollar bill slid between the gasket and door.

Compressor – Common sealed refrigeration compressors, like those made by Secop/Danfoss, are made by the thousands for commercial, marine and household use. Modern marine versions come in three sizes, BD-35/50/80. The Secop/Danfoss compressors’ electronic control modules determine what electrical supply is required (12/24 volt DC or 110/220 volt AC). These compressors all have resistor-controlled variable speeds at different amps allowing for adjustable heat removal capacities from an evaporator plate. The longer and slower a compressor runs the more efficient it is, amps vs. cooling. Therefore it is best to design any refrigeration system to be able to keep up with normal heat loads with the compressor running at its lowest speed. Also, if running at highest speed, an additional cooling fan is required for the compressor. Some helpful devices that work with these compressors are adjustable manual and automatic speed controls and an electronic thermostat.

These compressors are very robust and usually maintenance free for their service life. However, when something goes wrong inside it probably means a replacement is in order.

Cooling options – Air, water or external to the hull “keel cooler” are the choices. If electrical efficiency is important to you, consider that in the tropics power consumption of an air-cooled system will be somewhat higher than that of a water-cooled system, and very much higher than for a keel-cooler system. If using a keel-cooler system, without the need normally for a fan or water pump, you can still add an air-cooled option which makes cooling your system safer while on the hard. Running a keel-cooled system in air can be detrimental to the compressor.

Electronic Control Module (ECM) – This is the brains of a modern refrigeration system. It is a relatively small rectangular plastic box that plugs into the side of the compressor. Because it contains electronic components, it is heat and moisture sensitive. Therefore, it should live in a cool dry place.

Newer models have radio interference suppression and LED fault diagnosis capability. They have a vertical string of spade electrical connections that accommodate power and accessories such as fans, thermostats and speed controls. If the number of wires needing access to the two power connections at the top is more than a couple, it is best to rig a separate terminal block. The ECM also determines the electrical configuration of the compressor (12/24 volt and/or 110 volt, or 220 volt). It is the highest failure rate item in a refrigeration system and worth carrying a spare.

Evaporator plate – On a modern system these are the flat plates or small rectangular freezer units mounted inside a box that carry the heated refrigerant outside. They can be made of soft bendable aluminum or stainless steel. The aluminum is better at absorbing heat, but the stainless steel is more robust and less likely to puncture. Those with top loading boxes should consider stainless steel plates as there is more chance of damage from moving stacked food. They are sold in several sizes that match installation constraints and heat absorption requirements.

Mounted inside the tubing is a refrigerant-metering capillary tube which replaces the older expansion valve. A blocked capillary tube is a fairly rare, but difficult issue, and may require a gauge set and vacuum pump to resolve. Ensuring there is a filter/dryer in the compressor discharge line will usually prevent this. Recently-manufactured systems usually have a filter dryer as part of the condenser unit but older systems may not. Replacing the evaporator and capillary tube is expensive but will usually fix the problem.

Repair tips – After installation, a properly engineered, installed, and cared for modern marine refrigeration system should last at least 15-20 years without any major repairs or replacements. If properly done with good insulation, the cold box should last the life of the boat. However, since Murphy resides aboard many boats, and we sometimes don’t get it right the first time, the system and box sometimes need our help. Below are several maintenance, repair and other tips I have learned the hard way.

Refrigerant leaks – A refrigerant leak could be caused by many things including corroded tubing, a loose tubing connection, a deteriorated connection O-ring, and a punctured evaporator plate. Most leaks can be found, after pressurizing the system, by using dish soap and water solution or a commercial soapy cleaner like 409. If really small, an inexpensive electronic leak detector is useful. A hole in tubing will require removing the refrigerant, carefully sealing with silver solder, or adding a splice and use of a vacuum pump. Evaporator plate punctures usually require replacing the plate. Soldering or using metal epoxy like JBWeld might provide a temporary fix depending on the location of the puncture. Tube connection O-rings are easy to replace but require having a spare aboard.

Adding refrigerant – Adding refrigerant is a common maintenance action. On modern evaporator plate systems, this is best done by observing the frost line on the inside of the evaporator plate while adding refrigerant. Evaporator plate systems have too little refrigerant for gauge pressures to be very effective. Therefore refrigeration mechanics that show up with gauge sets to judge refrigerant status should be immediately suspect. Most modern marine refrigeration systems use a Schrader valve that gives access to the suction side of the compressor for adding refrigerant. Automotive systems use a different valve system compatible with devices that connect to the 12-ounce cans of R134a sold in automotive parts stores. So some jury rigging might be necessary in order to allow using the small can refrigerant with a marine hose gauge system. A better option is to buy a small R134a refillable can with a Schrader fitting. Make sure you don’t use any refrigerant that has additives such as leak sealers or dye.

A system is properly charged when the frost line migrates from the capillary tube entirely across the evaporator plate, stopping at the suction line or a couple inches beyond. SLOWLY add only R-134a refrigerant in SMALL amounts, until satisfactory. Never allow the frost line to reach the compressor or it may be permanently damaged.

a small

vacuum pump.

Gauges and vacuum pump – With the older cold plate system we had on the CSY, I found a gauge set, vacuum pump, compressor spares, flaring tools, tube cutters, and spare fittings to be essential. With modern Danfoss/evaporator plate systems, they are rarely used. However, they are certainly useful if Murphy climbs inside your system with moisture and dirt or you need to evacuate the system with a vacuum pump. As an overseas cruiser we carry a vacuum pump, gauge set, recharge connections and a refillable can of 134a. However, most AC and refrigeration mechanics here also have that equipment.

Hopefully, this information will be of use to those of you willing to learn more about building, improving or repairing your refrigeration system. A careful study of this information should be of help when you get that first professional quote for installing your new refrigeration system or repairing it later on. You should be at least as informed as that developing world mechanic you might consider paying to come aboard your boat and mess with your refrigeration

system. n

Dave McCampbell is a former US Navy officer who spent most of his time as a diving and salvage officer. He commanded the Rescue Salvage ship, Bolster, and two shore-based diving commands. He and his wife Sherry voyage on their St. Francis 44 Mark II cat Soggy Paws.