Shackle Selection is More Complicated Than it Looks

Maybe this has happened to you… you picked out a shackle, went to install it and discovered that it didn’t fit. Other times you’ve found that the shackle fit, but it didn’t have the work load limit (WLL) you needed. This is all very vexing, but as you read on, you’ll see that it doesn’t have to be.

There are standards that, when adhered to during manufacturing, assure that any one component will fit and have equitable WLLs with others — for shackles that standard is Federal Specification RR-C-271, often just referred to as “271.” Outside of the US, other countries may use different, albeit comparable standards.

Though Fed. Spec. 271 allows various types of finishes — self-colored, bright, paint, and zinc (galvanized) — for the longest, rust-free service, hot-dipped galvanized (HDG) is the coating of choice.

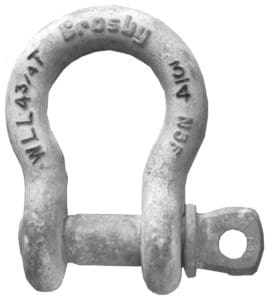

Another requirement of 271 is that the shackle’s body be embossed — raised letters or numbers — with its WLL, size, and manufacturer’s mark. In trade speak this is its hallmark.

If the WLL is not embossed, but instead stamped into it, the shackle is non-compliant with 271, and even if it has the requisite WLL, its dimensions likely will not fit with other components, particularly chain.

Unlike many components which have breaking loads (BL) that are usually four times their WLL, shackles manufactured to 271 will have BLs five times, some even six times that of their WLL. This is done to help offset the loss of strength that occurs when the load is not directly in line with the shackle, a common situation that frequently occurs when anchored. Regardless of this higher BL, choosing a shackle is based on its WLL, and this WLL remains sacrosanct.

Those ubiquitous regular-strength (carbon) shackles found in hardware stores, home improvement centers, and chandleries, if manufactured to 271, have dimensions and WLLs that are for use with Grade 30 chain, either Proof Coil or BBB.

High test issues

But, where most folks have problems is with “High Test” chain — ISO Grade 43, NACM Grade 43, Metric G40, or Australian Grade M. Only high-strength (alloy) shackles, manufactured to 271, are the shackles designed to fit and match WLLs with these High Test chains.

Unfortunately, alloy shackles are relatively unknown within the recreational boating community, even among many suppliers, chandleries or other retailers, but they are available. Look online, ask at a crane, rigging or industrial supply facility, or call a company that manufactures chain, as they might also manufacture alloy shackles, and if not, they may be willing to share the name of a company that does.

Shackles cannot function without a pin and the pins are more specialized than they might appear:

• Their diameters are one size larger than the embossed size of the shackle.

• They are often of a higher strength alloy than that of the body of the shackle, so replacing a shackle’s pin with just any old bolt can prove to be a dangerous practice.

• For ground tackle, only shackles that have threaded pins should be used, as a threaded pin reduces the opportunity for the legs of a shackle to spread, particularly when side loaded.

• The pins of alloy shackles are required by Fed Spec 271 to be stamped HS (High Strength) in raised letters. This stamping allows a user to differentiate a pin for a high-strength (alloy) shackle from that used in a regular-strength (carbon) shackle, which has a lower WLL and no special marking.

Cotter pins are known to fail or fall out, so using a pin in a shackle that is dependent on a cotter pin for security is ill-advised. Instead, to prevent a pin from backing out, a seizing is the better alternative and is best done with Monel or stainless steel wire; mousing and safety wiring are other terms that are interchangeable with seizing.

However, once seized, the ends of the twisted-together wire are exposed, enabling them to poke at passing fingers, ropes or sails. The solution, using needle nose pliers, is to bend the ends of the twisted wires together wires down, tucking them under the turns of the seizing between the seizing and the body of the shackle.

To keep threads from rusting (or with stainless steel, galling), coat the threads of pins with a water resistant product — Ultra Tef-Gel, petroleum-based, synthetic or silicone grease, anhydrous lanolin, Forespar’s Lanocote, and even petroleum jelly all work well for this job, and all need to be reapplied periodically.

Some manufacturers emboss the body of alloy shackles with a proprietary symbol that identifies the shackle as alloy, though this body marking is not a requirement of 271.

If this proprietary marking is absent from the body of the shackle, another way to determine if the shackle is a high-strength (alloy) shackle is to compare its embossed size and WLL with the specs, either in 271 or in the manufacturer’s literature, or you could compare the WLL of the shackle with a known shackle of the same size.

Horseshoes

Shackles suitable for anchoring come in two styles, either can be had with threaded pins — a horseshoe shape called a bow or anchor shackle, or D shape, called a chain shackle.

Though the horseshoe shape is the more common of the two, when used in ground tackle we find that D-shaped shackles don’t seem to kink up as frequently as do bow-shaped shackles.

The difficulty comes in finding D-shaped shackles, as they are manufactured only by a few companies, some of which are: Crosby, Chicago, Campbell, Columbus-McKinnon, and Titan Marine Products.

More challenging are D-shaped alloy shackles, which are manufactured by even fewer companies, two of which are Columbus-McKinnon and Titan Marine Products.

Stainless steel shackles are not covered in 271, thus their WLLs vary widely; few fit and equal the WLLs of Grade 30 chain, and none fit and equal the WLLs of Grade 43 chain.

Though some stainless steel shackles are manufactured with a hallmark, this only conveys information about the shackle, it does not indicate that it has been manufactured to 271.

It is important to know that shackles made from stainless steel, even 316L, are subject to problems that are inherent with this material, any of which can result in failure of the shackle:

• Stainless steel can, especially when used in saltwater, develop small cracks, some which are essentially invisible.

• Stainless steel is susceptible to oxygen deprivation when used in oxygen-poor water, such as water that is polluted or when buried in the seabed, allowing pitting and crevice corrosion to develop.

• Stainless steel has poor elongation properties, providing little warning that it had reached or is reaching its point of failure.

Scheduled replacement

Due to the problems noted above, in order to minimize failures, at least one manufacturer recommends replacement of their product, a stainless steel swivel that incorporates a shackle, every five years. We, too, strongly endorse this practice, not only for stainless steel shackles, but for any stainless steel item that is used in ground tackle.

In addition to the 300 series of stainless steel shackles, duplex stainless steel shackles are also available. Though duplex stainless steel shackles have a higher corrosion resistance, there are several challenges that may need to be overcome:

• When comparing duplex stainless steel shackles with high-strength (alloy) shackles of comparative pin diameters, little if any difference in WLLs is noted. However, a strength advantage is noted when compared to 316L stainless steel shackles.

• Duplex stainless steel shackles cost significantly more than 316L, carbon or alloy shackles. Pricing has been observed to be as much as seven times that of the other more common shackles.

• The only source the author has been able to locate for duplex stainless steel shackles is from manufacturers in the UK. If you’re buying from companies in foreign countries, in addition to the purchase price, you’ll also need to consider the additional costs of handling, shipping and VAT; plus, possible time delays due to shipping.

• You will most likely have to deal in metric measurements, though this is easily done using one of the conversion calculators found on the internet or one of the formulas found in many math or engineering books.

• As with domestic shackles, you should purchase only those shackles that are manufactured to an applicable standard and that show the appropriate hallmarks. Hallmarks on duplex stainless steel shackles are usually etched on, not embossed.

Understanding these points offers you the opportunity pick the right shackle the first time, and then anchor with the knowledge that there is one less potential weak spot in your ground tackle. n

Rudy and Jill Sechez have lived aboard and cruised since 1997. They are the authors of Anchoring- A Ground Tackler’s Apprentice available as hard copy, app or e-book. You can hear them speak at TrawlerFest, Cruisers University, many West Marine Stores, as well as at many boat or yacht clubs. Contact them at rudysechez@gmail.com; visit their website at trawlertrainingabc.com.