Refrigeration trends for voyagers

Whenever cruising boaters gather marine refrigeration is always a hot topic. Back in the day it was a lot more controversial due to the prevalence of competing system philosophies, but what was once the new kid on the block now dominates. And the winners, by a long shot, are the many different 12-volt powered systems, either in self-contained refrigerators that are semi-permanently installed or as the cooling equipment for a custom built-in fridge.

In the past you used to see a lot of rugged, long-distance cruising boats with refrigeration compressors powered by belts from the main engine, or in some cases running on 12/24 volts or 120/240 volts from a generator. These compressors were used to bring down the temperature of big holding plates that maintained the cold for many hours. I used to have a 12-volt Crosby system like this and an hour or two of engine time could cool the chest down for four to six hours, or more, depending on the air and water temperature. The main disadvantage of these systems were obvious: large compressors, often attached to the engine, large holding plates with complex plumbing and wiring, and all sorts of components to install. They often required maintenance by skilled personnel, if you could find the right people when in some remote port.

Many years ago I sailed offshore from North Carolina to Puerto Rico and then the Virgin Islands. After arriving in St. Thomas we met some cruisers on a gorgeous offshore sailboat with an engine-driven compressor supplying a big fridge. While offshore and running the engine the compressor bracket broke and the unit took out the alternator with it. In one fell swoop they lost their refrigeration and their ability to generate 12-volt power. By the time they arrived in St. Thomas they couldn’t start the engine, had no fresh food, no running lights, and most of the electronics were offline. It made for a lousy trip, and an expensive and long repair job while at anchor. Unfortunately, tales like this are common amongst the cruising fleet. This is one reason that smaller, simpler, and easier-to-swap-out 12-volt systems have become so popular.

The 12-volt approach

The reason for the prevalence of 12-volt systems on most long-distance craft under around 50 feet is that most boats are already utilizing a variety of systems to generate abundant amounts of 12-volt power that is then stored in huge battery banks. Many boats sport solar panels, wind generators, and large engine-driven alternators, with battery banks capable of storing enough juice to go for days without starting the main engine. I lived for 12 years onboard a small catamaran that was completely powered by solar and wind, though we only maintained a tiny 12-volt portable fridge. When plugged into shore power the fridge still ran directly from the boat’s 12-volt system, while a normal marine battery charger plugged into shore power kept the batteries topped up. Since most boats are likely to already have these 12-volt systems in place, it vastly simplifies the installation and maintenance of the refrigeration part of things.

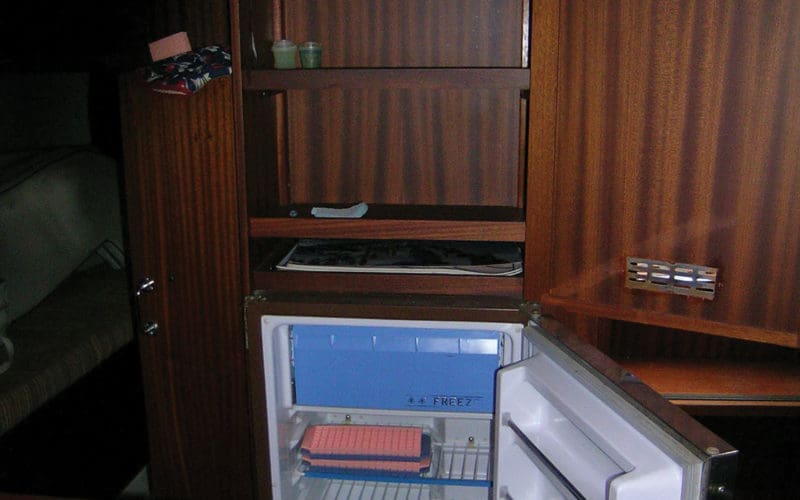

The installation of a self-contained 12-volt fridge is easy, and well within the capabilities of many cruisers. Lifespans typically range up to 20 years or more. On my boat an old Norcold fridge finally gave up the ghost after more than 40 years of use! A lot of these fridges include built-in inverters so they can be run directly off of shore power when needed, making them ideal for marina use. There are portable ice-chest sized 12-volt fridges that are just plug and play simple, and can be easily moved around the boat or carried ashore. You can find many name brand and numerous off-brand portable fridges all over the Internet and on Amazon.

Many 12-volt built-in fridges utilize the same evaporative cooling systems used in the self-contained fridges. Again, the units are designed for easy installation with minimal skills, and provide a quick and dirty way to transform an old “ice box” into a real refrigeration unit. The evaporative systems utilize thin, flat cooling plates that take the liquid coolant as it exits the compressor, allowing the coolant to rapidly expand into a gas, which pulls heat out of the plates and therefore the air of the refrigerator. The gas is then condensed, then compressed back into a liquid, and then back into the plates. Repeat over and over to maintain the correct temperature. This setup is the same as the big fridge in your kitchen at home. These systems are relatively efficient, but do cycle off and on constantly. When using one onboard you get a feeling after awhile for how hard the refrigeration is working by how often you hear the compressor run. I note the same thing when in my kitchen, and more than once I have been alerted that the fridge door was left ajar when I heard the compressor clicking on a lot.

Some manufacturers make DC-powered holding plate systems that combine most of the advantages of the old engine-driven compressor systems with the efficiency and simplicity of the 12-volt evaporative systems. The holding plates are much bigger and thicker than the evaporative plates, though they operate on a similar principal. The plates contain a solution that freezes as the coolant is circulated, evaporated, and then re-compressed. Eventually, after running for awhile, the holding plates become like big blocks of ice, though of course contained in metal. These icy holding plates maintain their temperature much longer than the thin evaporative plates that do not contain a frozen material.

Sea Frost has long been one of the leaders in marine refrigeration, and they are a one-stop shop for proven versions of both evaporative and holding plate systems, and they also have engine-driven compressor setups that are much more compact and simple than older units. The manufacturer believes that engine-driven holding plate systems are the ultimate in efficiency for long-distance cruising, resulting in the least amount of engine run-time. Of course, if you already have abundant 12-volt power from solar and wind, these advantages might not appeal as much. Sea Frost also offers 12/24 volt systems, with or without large holding plates.

Extending compressor cycles

The big advantage of the holding plates is they can extend the time between compressor cycles dramatically, which can work well for a boat that stays at anchor overnight, but then powers all day or can take advantage of the sun and wind. Holding plates act like big batteries, storing cold for periods when the refrigeration isn’t running.

Both evaporative and holding plate systems have become quite efficient. Technically, holding plates provide the ultimate in efficiency and the minimum total power consumption, but might in reality be overkill for many boats that have abundant 12-volt power from the sun and wind, or the engine. In my experience, many typical 12-volt marine fridges draw around 5 amps when running, and burn as much as 120 amps in 12 hours in hot climates. If you have a well-insulated box you might cut that draw in half. However, a lot of boats I see are also generating more than enough solar and wind power each day to cover the fridge and more. These numbers can be vastly improved by adding water cooling, better insulation, cooling fans, and good box design.

One thing to keep in mind is that cold air sinks and when you open the door on a typical refrigerator at home you will feel a cold blast on your feet. The same thing happens on a boat. Front opening fridges are not as efficient as top opening ones, but you do give up convenience if you have to dig down through layers to get at stuff in the bottom of the fridge. There are also drawer-type units that combine some of the advantages of having a door and also not letting all the cool air spill out. Frigonautica makes a variety of stainless steel drawer-type fridges.

One further factor on a sailboat is you need to keep in mind how you will access the fridge if the boat is heeled down. I’ve received some nasty bumps when the fridge door burst open on a heeled boat spilling out bottles and cans. There has to be some sort of latch to keep the door closed even in the roughest seas, or you will have to do like I did once on a trawler I was skippering. The fridge refused to stay closed so we would lash a rope around it whenever headed offshore.

A good idea when running 12-volt fridges is to keep the electrical draw separate from the engine starting battery bank. Because many 12-volt systems run nearly continuously, it is very easy to draw down a battery bank inadvertently. On my boat I utilize one big house battery bank that handles all the major draws, and is charged daily via solar panels and when the engine is running. A separate engine starting battery is only used for that purpose, and can’t be discharged by the refrigeration or anything else. A simple Trik-L-Start unit charges the engine starting battery and keeps it topped off whenever there is extra juice in the main battery bank. Unless there is a short or failure in the system, there is no way to draw down the starting battery by accident. Do not depend on crew remembering to put some switch in some position! It will be forgotten.

Other leading manufacturers of marine refrigerators and cooling systems for built-in installations include Dometic (Adler Barbour), Frigonautica, Isotherm, Norcold, Nova Kool and Frigoboat. Frankly, there are very few differences between the major brands of 12-volt evaporative refrigerators and refrigeration units. Many utilize the same compressor system, built by Danfoss. If you already have a built-in fridge you are replacing, just choose one that fits and don’t worry too much about the brand. As I stated earlier, these things last decades and with no maintenance. If you’re looking to install your own system, the details and differences will matter more to you.

Keeping the cold in the box

Insulation is the key to making any refrigeration system efficient. If you’re planning on some long-distance cruising in tropical climates you must pay attention to insulation first, and make plans for how the heat generated by the unit will be dissipated. When insulation is not ideal explore ways to add external insulation. For example, I was able to spray in foam insulation around parts of a built-in ice chest on an old sailboat, and then I put insulating foam on the outside of the lid. Be extremely careful with expanding foam insulation as the pressure it creates could damage the box or structure of your boat, and the process generates heat.

I’ve also used external foam sheets to enclose portable refrigerators to vastly improve their performance. Some people add internal insulation, which also reduces the area that has to be kept cold. The smaller the area to cool, the lower the power usage. One simple way to improve the performance of any fridge is to use small, soft-sided coolers or insulated bags inside the main box. If you have a large, top-loading box this can also make it easier to separate and retrieve various layers of items. Store the most vulnerable foods in the lowest levels of the chest where the temperature will be the lowest. Strategic layering in a deep chest can make a huge difference. One trick I use is to add plastic bottles of water as the amount of food declines in the chest. The water will stay cold for much longer than air and helps to reduce power consumption. If you have a freezer section, make sure you keep it either stuffed full of frozen food, or else fill it up with some of those blue freezer blocks used in portable ice chests. Keep a small thermometer right in the fridge to make sure it is getting cool enough.

There are water-cooled versions of many 12-volt systems that can improve their efficiency, particularly when air-cooling the units is not ideal. Needless to say, adding better insulation and water cooling with a through hull fitting with seacock, hose, a pump, additional wiring, etc., adds to the complication, but can result in dramatic power savings. The Sea Frost engine-driven system mentioned above utilizes a water cooled compressor.

There are various combinations of all of these systems. You can have an air-cooled system with evaporative plates, or you can go watercooled with the evaporative plate. Or, you can go to holding plates, with either air or water cooling. Then you can also add external fans with thermostatic control to improve the ventilation of the air-cooled systems.

Needless to say, it is important to maintain air flow with the air cooled units, and to maintain a good flow of water by making sure the through-hull doesn’t get clogged with barnacles or crud. It is a good idea to have a strainer on the water line to prevent seaweed and other bad stuff getting to the pump and beyond. Any system with water in the lines must be fully winterized if you store your boat where temperatures are likely to fall below freezing.

Thermoelectric cooling?

You may have heard of or seen thermoelectric coolers that look like big ice chests. Instead of moving parts, such as a compressor, they utilize what is called the Peltier effect that basically involves electricity flowing between two metals, generating heat on one side and a cooling effect on the other side. I won’t go into the details, but it does work nicely to cool down an insulated chest, but typically requires a continuous flow of electricity. The result is higher power consumption and less cooling – they are generally limited to dropping the temperature inside the box to about 40 degrees less than the ambient temperature. Obviously, if it is 90 degrees F inside your boat and the box can only get down to 50F it won’t be much good other than providing a coolish beverage or two. Storing cold food for long periods would be out of the question. While cruising in the Caribbean typical interior temperatures on our sailboat were often 80F or more, making a thermoelectric unit nearly useless.

The basic physics of refrigeration have not changed since the first experiments in the 18th and 19th centuries, and the first Frigidaires had all the major components we see today in household units. Marine refrigeration has become almost a commodity now. There are numerous brands with reliable, efficient systems, mostly running on 12 or 24 volts. In my experience, it is hard to choose one over the other, and many utilize the same or very similar components. It is still possible to get quality, engine driven compressor systems, like the Sea Frost units, but most cruisers seem happy going with simpler DC-powered versions, with or without holding plates. The main factors to consider are fit, features, and your boat’s power supply.

John Kettlewell is the executive director of Sail Martha’s Vineyard, and the author of numerous cruising guides, articles, and other nautical books. He’s sailed the waters between Labrador and the Caribbean for more than 40 years.